Hydraulic and Pneumatic Solutions for Heavy-Duty Manufacturing Applications

【Introduction】 Hydraulic and Pneumatic Solutions for Heavy-Duty Manufacturing Applications

Heavy-duty manufacturing relies on stable motion control, repeatable force output, and predictable system response. In sectors such as metal fabrication, automotive components, and energy equipment, hydraulic and pneumatic systems continue to play a central role. We see these technologies frequently integrated with automation equipment, particularly end effectors for robots, where controlled gripping, pressing, or positioning is required. In China’s industrial supply chain, hydraulic and pneumatic solutions are valued for their adaptability to different load conditions and production rhythms. As a supplier-focused exhibition platform, ITES Shenzhen has long observed how manufacturers combine fluid power with robotic interfaces to address high-load, high-frequency tasks while maintaining operational consistency across shifts and production lines.

Hydraulic and Pneumatic Technologies in Heavy-Duty Automation

Hydraulic systems are commonly applied when high force density and smooth linear motion are required, such as stamping, bending, or clamping operations. Pneumatic solutions, by contrast, are often selected for faster cycles, lighter loads, and simpler system layouts. In heavy-duty manufacturing, these two approaches are frequently used together within robotic cells. We often encounter scenarios where an industrial robot end effector integrates pneumatic grippers for rapid handling while relying on hydraulic units elsewhere in the line for forming or compression processes. For Chinese manufacturers, the ability to source standardized components locally while customizing interfaces for robotic tooling is a practical advantage. This flexibility supports scalable deployment of end effectors for robots across different models and payload classes without redesigning entire systems.

Supply Chain Integration and Product Adaptation

From our perspective, one of the defining characteristics of China’s industrial ecosystem is the close coordination between component suppliers, automation integrators, and end users. Hydraulic cylinders, valves, air preparation units, and sensors are often developed with compatibility in mind, allowing smooth integration into robotic tooling assemblies. When designing an industrial robot end effector, manufacturers can select pneumatic or hydraulic actuation based on load, speed, and maintenance expectations. We introduce product solutions that emphasize modular interfaces, material durability, and compatibility with common robot brands, as outlined in our product topic resources. This approach helps reduce engineering complexity while maintaining performance consistency in demanding production environments, especially where end effectors for robots must operate continuously under variable conditions.

Exhibition Focus on Practical Manufacturing Solutions

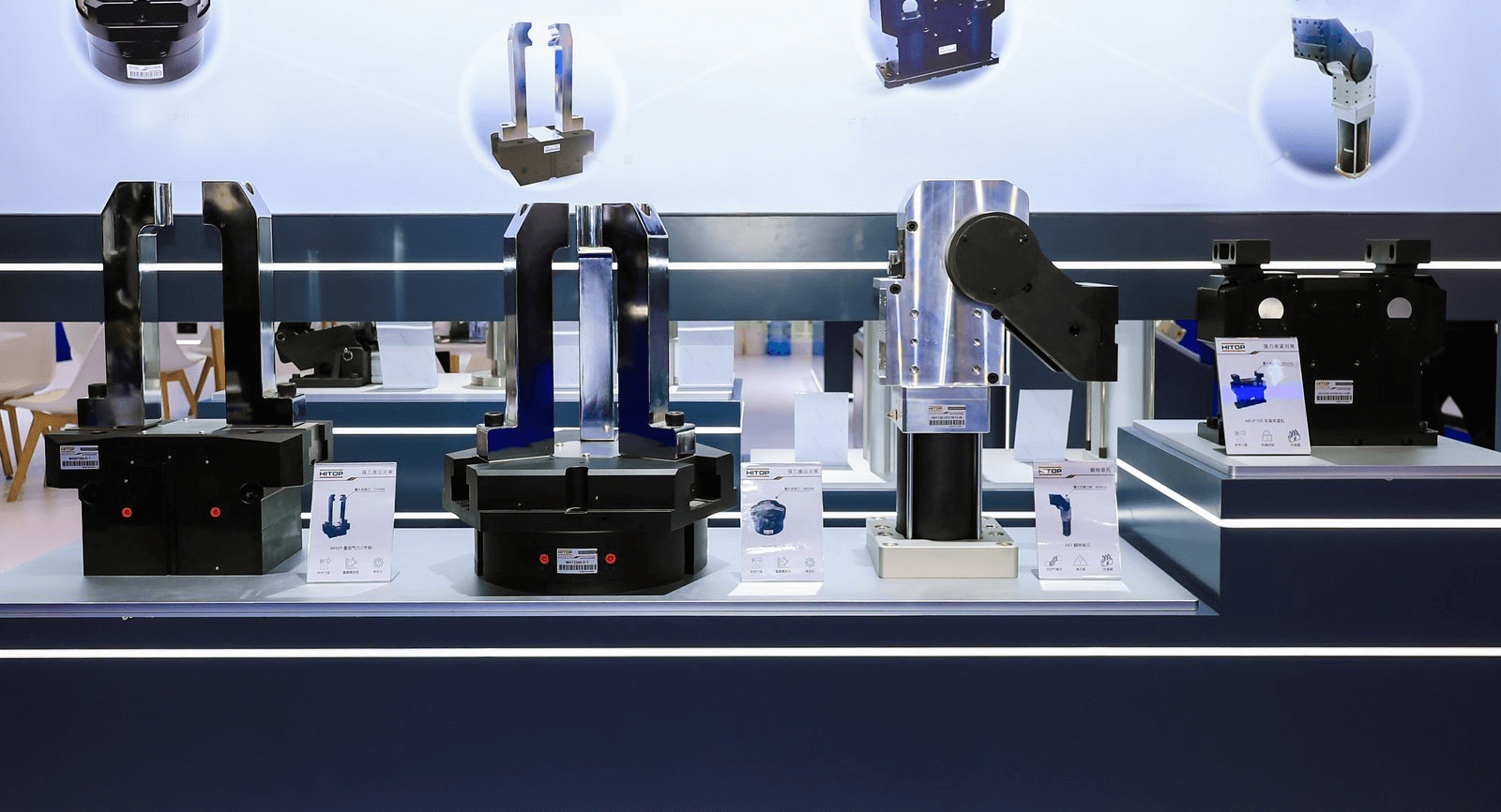

As an industrial exhibition serving advanced manufacturing, ITES China places strong emphasis on real-world application scenarios. At the show, we highlight hydraulic and pneumatic technologies through complete automation demonstrations, including robotic cells equipped with gripping, clamping, and positioning tools. Visitors can review how an industrial robot end effector is configured for heavy-duty handling, as well as how upstream fluid power systems support stability and repeatability. Exhibitors present components, assemblies, and integrated solutions covering metalworking, electronics manufacturing, and energy-related production. By connecting suppliers and system integrators, the exhibition helps manufacturers evaluate how end effectors for robots and fluid power technologies can be combined effectively within modern production lines.

Conclusion: Connecting Fluid Power and Automation at ITES China

The continued relevance of hydraulic and pneumatic solutions in heavy-duty manufacturing reflects their reliability and adaptability. When paired with robotic systems, these technologies enable flexible automation without sacrificing load capacity or control precision. We believe that understanding how end effectors for robots interact with fluid power systems is essential for manufacturers planning upgrades or new installations. Through ITES China, we provide a platform where suppliers, integrators, and users can explore practical configurations, review component compatibility, and discuss application-driven requirements. This exchange supports informed decision-making and encourages balanced adoption of automation technologies, including the effective use of industrial robot end effector solutions in complex manufacturing environments.