What Is a Deep Hole Drilling Machine? A Comprehensive Guide for Industrial Buyers

【Introduction】 What Is a Deep Hole Drilling Machine? A Comprehensive Guide for Industrial Buyers

A deep hole drilling machine is a specialized piece of equipment designed to create precise, deep, and narrow holes in various industrial materials. Unlike conventional drilling machines, it employs a unique mechanism that ensures high accuracy and stability when drilling deep into metals such as steel, aluminum, or alloys. Our system works by feeding a cutting tool through the material while continuously flushing the hole with coolant, which removes chips and maintains consistent temperature. At ITES China, we showcase these machines to help industrial buyers understand their functionality and advantages. As a leading exhibition in ITES Shenzhen, we connect visitors directly with China drilling machine manufacturers.

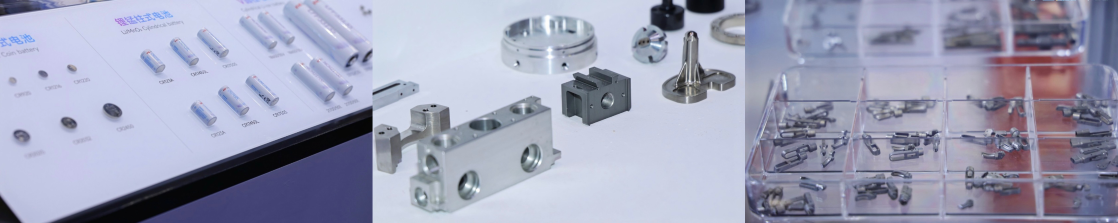

Key Components of a Deep Hole Drilling Machine

A deep hole drilling machine consists of several critical parts that ensure precision and efficiency. The spindle and feed mechanism control the cutting tool’s motion, while the guide bush stabilizes the tool in the workpiece, preventing deviation. The high-pressure pump delivers coolant directly into the drilling area, ensuring proper lubrication and chip removal. At our ITES Shenzhen exhibition, we highlight how different deep hole drilling machine manufacturers integrate these components to meet diverse industrial needs, from aerospace to automotive manufacturing. By understanding these parts, buyers can make informed choices when selecting equipment for their operations.

Industrial Applications

Industries that require deep and precise holes benefit significantly from these machines. Common applications include crankshaft production, hydraulic components, and precision molds. For example, automotive suppliers rely on deep hole drilling machines to maintain tight tolerances in engine parts, while aerospace manufacturers use them for structural components that demand high accuracy. Our team at ITES China emphasizes these real-world applications, demonstrating how Chinese drilling machine technology improves production efficiency and consistency across multiple sectors.

Why Many Companies Choose China Deep Hole Drilling Machines

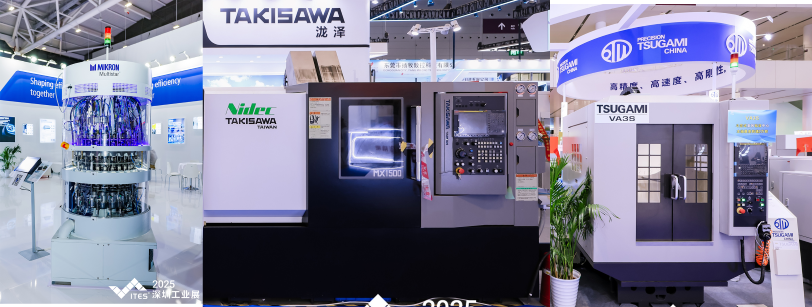

China’s manufacturing expertise has made China drilling machine solutions increasingly popular worldwide. Companies choose Chinese equipment for its cost-effectiveness, advanced design, and adaptability to various industrial requirements. Deep hole drilling machine manufacturers in China offer machines that balance speed, precision, and durability, making them suitable for both small workshops and large-scale production. At ITES Shenzhen, visitors can see firsthand the innovations Chinese suppliers bring to the table and learn how their machines can fit into existing production lines without significant adjustments.

Where to Meet Deep Hole Drilling Machine Suppliers

For industrial buyers seeking direct interaction, trade exhibitions like ITES China provide an ideal platform. At ITES Shenzhen, visitors can discuss technical specifications, observe live demonstrations, and compare multiple deep hole drilling machine manufacturers under one roof. This face-to-face communication allows buyers to evaluate machine performance, ask detailed questions, and establish connections that go beyond online research. Participating in such events ensures that companies make well-informed decisions when integrating new drilling technology into their operations.

Conclusion: Leveraging Expertise for Industrial Success

Understanding what a deep hole drilling machine offers is essential for industrial buyers seeking precise and reliable equipment. Through ITES China and its ITES Shenzhen exhibition, we provide insights into machine components, applications, and supplier options. By exploring the offerings of China drilling machine manufacturers, companies can identify solutions that improve operational efficiency, reduce downtime, and maintain high standards of quality. Engaging directly with suppliers helps ensure that your investment aligns with your production goals and long-term industrial strategy.