Types of Drilling Machines Used in Industrial Manufacturing

【Introduction】 Types of Drilling Machines Used in Industrial Manufacturing

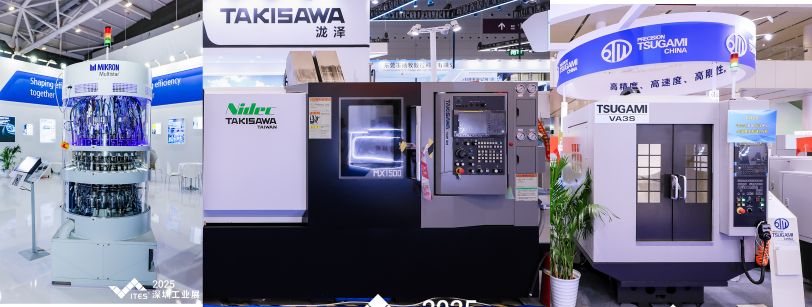

In industrial settings, a drilling machine plays a central role in creating holes with precision and repeatability. When we refer to a drilling machine, we mean a mechanical tool designed to produce cylindrical holes in metal, wood, or composite materials. At our company, ITES China participates in trade shows that highlight the latest China drilling machine technologies and innovations. We witness how these tools support a wide range of applications, from fabricating structural frames to refining complex assemblies. Understanding what a drilling machine does is the first step to selecting equipment that aligns with specific manufacturing goals, whether the task demands accuracy, speed, or adaptability.

Vertical, Bench, and Deep Hole Drilling Machines

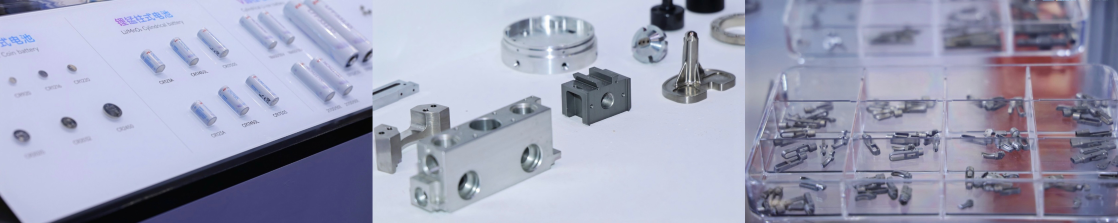

Industrial needs call for different drilling machines, including vertical, bench, and deep hole types. A vertical drilling machine features an upright head for precise hole depths and is often paired with automated feeds for consistent results. Drilling machine manufacturers commonly offer this type for general fabrication. Bench drilling machines are compact, designed for workbenches, and suit medium-duty tasks in limited spaces. At events with China drilling machine manufacturers, bench units attract attention from businesses optimizing small production cells. Deep hole drilling machines produce long, narrow holes with advanced cooling and chip removal, serving industries like aerospace and automotive where precision over extended lengths is essential.

How to Select the Right Drilling Machine

Selecting the right drilling machine requires evaluating key factors. Material properties such as hardness, thickness, and tolerances influence the choice, with tougher materials needing higher torque and robust spindles. Drilling speed and feed rate should align with production demands, and insights from drilling machine manufacturers help balance throughput with finish quality. Modern machines often integrate with production systems or monitoring software, and at ITES China we see how connectivity features enhance operational efficiency and transparency.

Advantages of Choosing China Drilling Machine Manufacturers

Partnering with reputable China drilling machine manufacturers provides practical benefits. These suppliers combine engineering expertise with flexible production, offering customization such as spindle options and cooling systems to match specific needs. Many drilling machine manufacturers also provide scalable solutions, from single units to full production fleets, supporting gradual investment. Through ITES China, we access diverse portfolios—from compact bench machines to deep hole drilling systems—helping customers select equipment that meets current requirements while allowing future expansion.

Meet Drilling Machine Manufacturers at ITES 2026

As we look forward to ITES China 2026, we see it as an opportunity to engage directly with leading China drilling machine producers. The show provides a platform where we and our industry partners can explore innovations in drilling technology and discuss emerging trends with experienced drilling machine manufacturers. Participating in this event helps us stay informed about advancements that can enhance manufacturing workflows.

At ITES 2026, visitors will have the chance to see live demonstrations, compare technical specifications, and consult with engineers about specific applications. For companies evaluating new drilling equipment or planning upgrades, this environment supports informed decision-making and builds connections that extend beyond the event floor.

Conclusion: Integrating Knowledge and Practice

Understanding the types and applications of drilling machines is essential for manufacturers aiming to optimize production quality and efficiency. By learning about vertical, bench, and deep-hole drilling machines and by carefully considering selection criteria, we equip ourselves to make better-informed decisions. Engaging with drilling machine manufacturers and exploring offerings from Chinese drilling machine providers, particularly through platforms like ITES China, strengthens our ability to match solutions with real manufacturing needs. As we prepare for ITES 2026, we remain committed to supporting our partners with insights and tools that contribute to sustainable operational growth.