Selecting the Right Ball Screw for High-Speed CNC Applications

【Introduction】 Selecting the Right Ball Screw for High-Speed CNC Applications

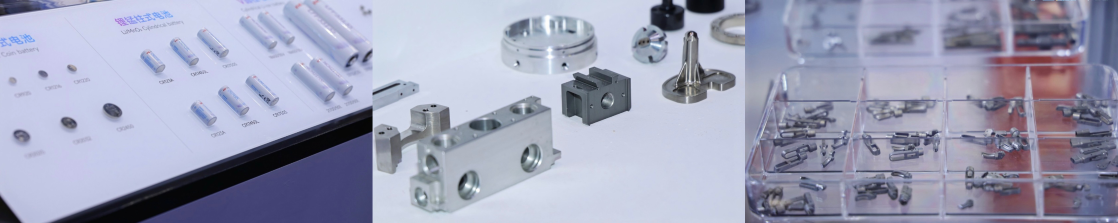

When working with high speed CNC machines, choosing the right China ball screw can dramatically influence precision, speed, and durability. In high precision machining, a ball screw serves as a core mechanical component that translates rotary motion into linear motion with minimal friction. At its heart, the design of the China ball screw determines how efficiently it can maintain accuracy at elevated speeds. For manufacturers and engineers in industries like aerospace, automotive, and industrial machinery, understanding the characteristics of different ball screw configurations helps determine which assembly fits specific operational needs. Within this technical context, recognizing the benefits and limitations of alternative designs is the first step toward selecting the proper part for high speed CNC operations.

Why Working with a Reliable Ball Screw Manufacturer in China Matters

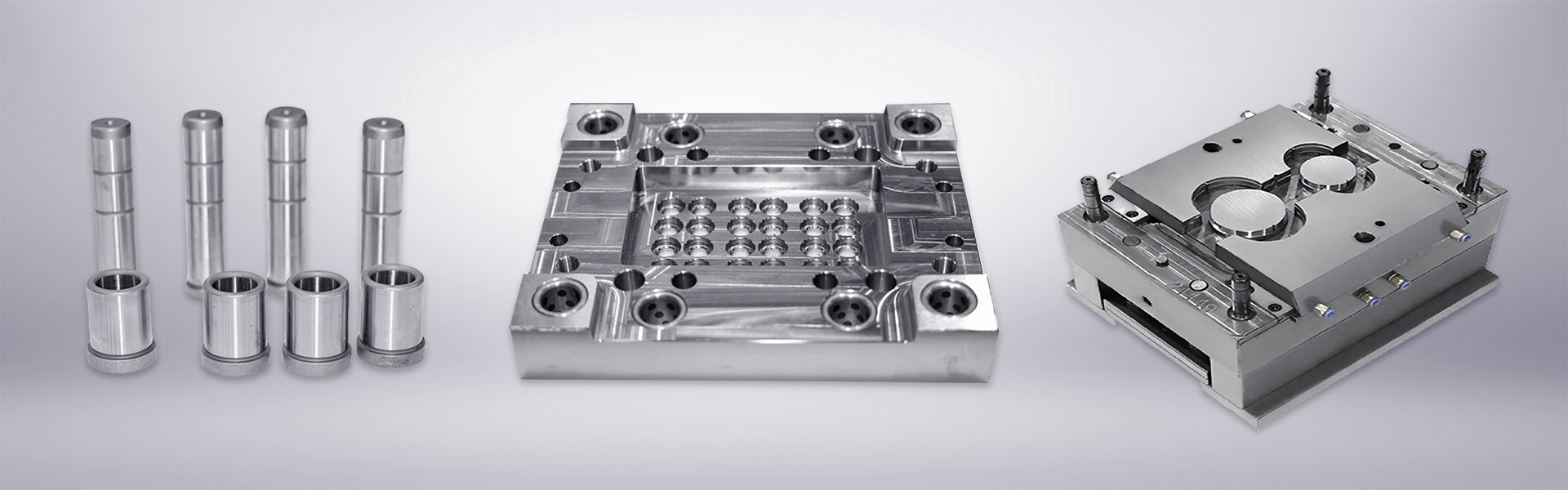

In our experience at ITES China, collaborating with a qualified ball screw manufacturer in China brings tangible advantages for high speed CNC applications, especially in supply chain continuity and customization options. Our company has observed that suppliers based in China can offer a range of lead screw geometries, preload options, and accuracy grades that suit different spindle speeds and dynamic loads. When evaluating a ball screw manufacturer in China, it is essential to assess not only product specifications but also production capabilities, quality control processes, and delivery timelines. These assessments reduce the risk of unexpected downtime and help ensure that high speed machining systems operate within design parameters. Through consistent evaluation and communication, we have strengthened our ability to deliver solutions that meet the exacting needs of clients across diverse markets.

Practical Tips for Selecting High Speed Ball Screws

Selecting the correct China ball screw for a high speed CNC application requires attention to several technical factors. First, you should match the lead and diameter to the required feed rate and stiffness, since both parameters influence acceleration and positioning accuracy. Second, consider the preload class and return system type; these aspects affect vibration damping and back lash behavior under rapid directional changes. Third, we recommend reviewing thermal expansion and lubrication methods to help maintain performance during extended machining cycles. At ITES China, we emphasize that striking the right balance between speed, precision, and life expectancy is crucial. Partnering with a seasoned ball screw manufacturer in China enables engineers to align product design with real world machining challenges, ensuring that the mechanical transmission system supports overall machine productivity.

Exhibit Highlights: Showcasing Cutting Edge Solutions at ITES Shenzhen

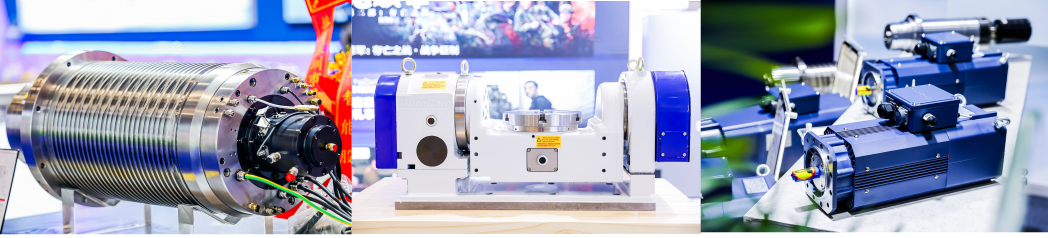

At this year’s ITES Shenzhen event, we are excited to present our latest high speed ball screw solutions alongside complementary linear motion technologies. The exhibition features in depth discussions on precision motion systems, live demonstrations of advanced CNC platforms, and expert panels addressing emerging trends in automation. As a company exhibiting at ITES Shenzhen, we have curated product displays that highlight variations of ball screw assemblies suitable for high speed environments, including high preload variants and custom coatings designed for extended life. Visitors can engage with technical specialists to explore practical integration strategies, compare performance data, and gain insight on supply chain options. With manufacturers and solution providers from around the world participating, ITES Shenzhen serves as a dynamic environment to strengthen industrial partnerships and stay informed about next generation motion control technologies.

Conclusion: Integrating Expertise with High Speed CNC Motion Control

Selecting the right China ball screw for high speed CNC applications ultimately blends engineering insight with practical supplier evaluation. By working with a trusted ball screw manufacturer in China, and engaging directly with experts at events like ITES Shenzhen, we position our teams and customers to make informed decisions that support reliability and long term performance. In conclusion, understanding key design considerations, evaluating supplier capabilities, and leveraging industry exhibitions collectively empower manufacturers to optimize their high speed CNC systems confidently.