What Is a Ball Screw Used For

【Introduction】 What Is a Ball Screw Used For

A ball screw is a precision mechanical component widely used in modern manufacturing and automation. When we talk about high precision motion systems, understanding what a ball screw is used for becomes essential for engineers and procurement teams alike. At ITES China, we have witnessed first hand how China ball screw solutions enable accurate motion control across diverse industries. In this article, we share insights on what ball screws do, why they matter, and how choosing a reliable ball screw manufacturer in China supports global supply chains and industrial innovation.

Understanding Ball Screw Applications

When we ask, what is a ball screw used for? The core answer is that ball screws convert rotational motion into linear motion efficiently and precisely. This mechanism consists of a threaded shaft and a nut assembly with circulating ball bearings, minimizing friction and achieving high mechanical efficiency. In applications such as CNC machines, robotics, and industrial automation systems, this efficiency translates into smooth linear motion and fine positional control, which are critical in precision machining and assembly environments. Ball screws also support heavy loads and high speed operations, making them a key choice for advanced automation.

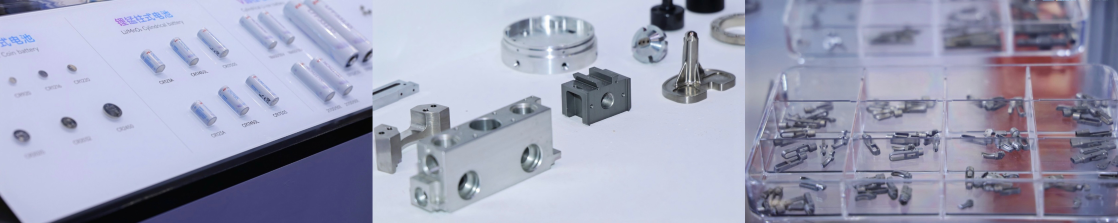

Beyond machining centers, ball screws find use in aerospace systems, automotive manufacturing equipment, semiconductor handling machinery, and medical devices. In aerospace and automotive applications, they help ensure actuation systems respond accurately under varying loads, delivering consistency and reliability. In electronics and semiconductors, ball screws provide repeatable precision, supporting production of high density circuit boards and automation tooling.

Why China Ball Screw and Supply Chain Strength

As an exhibitor and industry participant, ITES China frequently engages with international buyers searching for reliable ball screw manufacturers in China as partners. China’s manufacturing ecosystem offers mature production clusters, advanced machining infrastructure, and competitive supply chains that contribute to reduced lead times and cost effective quality components. Regions such as Zhejiang and Jiangsu host dense networks of suppliers specializing in linear motion components, enabling flexibility in custom orders and shorter delivery cycles compared to many alternatives.

We have observed that collaborating with a China ball screw supplier helps many companies streamline procurement, especially where high volume or specialized configurations are required. Chinese producers often balance precision machining with cost managed delivery, which supports both OEM projects and research driven developments. The result is not merely a product, but an integrated solution that aligns with global manufacturing demands.

ITES China Exhibition Highlights

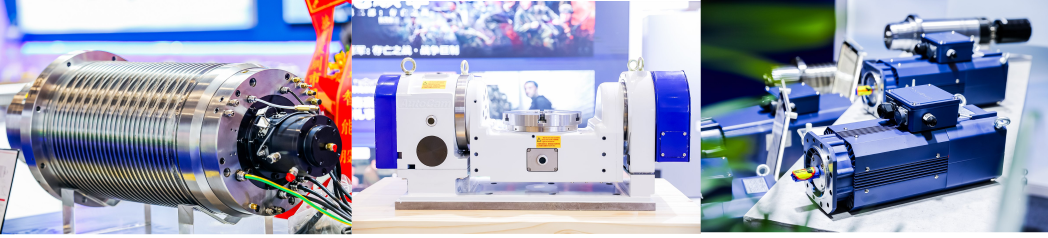

As we prepare for the upcoming ITES China exhibition, this platform becomes an ideal stage to explore innovations in ball screws and related components. The upcoming event in Shenzhen showcases a Core Functional Components zone highlighting spindles, rotary tables, precision tools, and crucially, ball screws. Exhibitors include leading motion system brands and suppliers who will present solutions for 3C electronics, automotive manufacturing, medical precision equipment, and more.

Visitors can expect demonstrations of advanced ball screw designs, direct dialogues with manufacturers, and insights on emerging trends in automation technology. For professionals seeking deep understanding of what a ball screw is used for, the exhibition offers a rare opportunity to compare products, understand technical nuances, and assess supply chain options firsthand.

Conclusion: Precision Motion and Industrial Growth

In summary, understanding what a ball screw is used for underscores its role as a foundational element in precision linear motion systems. We at ITES China recognize that ball screws enable critical motion control across sectors like machining, robotics, aerospace, and semiconductor manufacturing. Choosing the right ball screw manufacturer in China not only provides accurate component solutions, but also strengthens integration with global supply chains. As industry demands evolve, the efficient, high precision capabilities of ball screws will remain central to innovation across manufacturing ecosystems.