Drill Bits: How to Select the Best Tool for Metalworking

【Introduction】 Drill Bits: How to Select the Best Tool for Metalworking

Metalworking starts with the right tools, and choosing the right drill bit is essential for precision and efficiency. At ITES China, we recognize that metalworking demands careful consideration of material hardness, coating, geometry, and cutting speed. When evaluating drill bits from Chinese suppliers, it’s important to distinguish between quality manufacturers and commodity-grade products. In this article, we share our insights to help you make informed decisions and show how our participation at ITES Shenzhen brings these solutions to life.

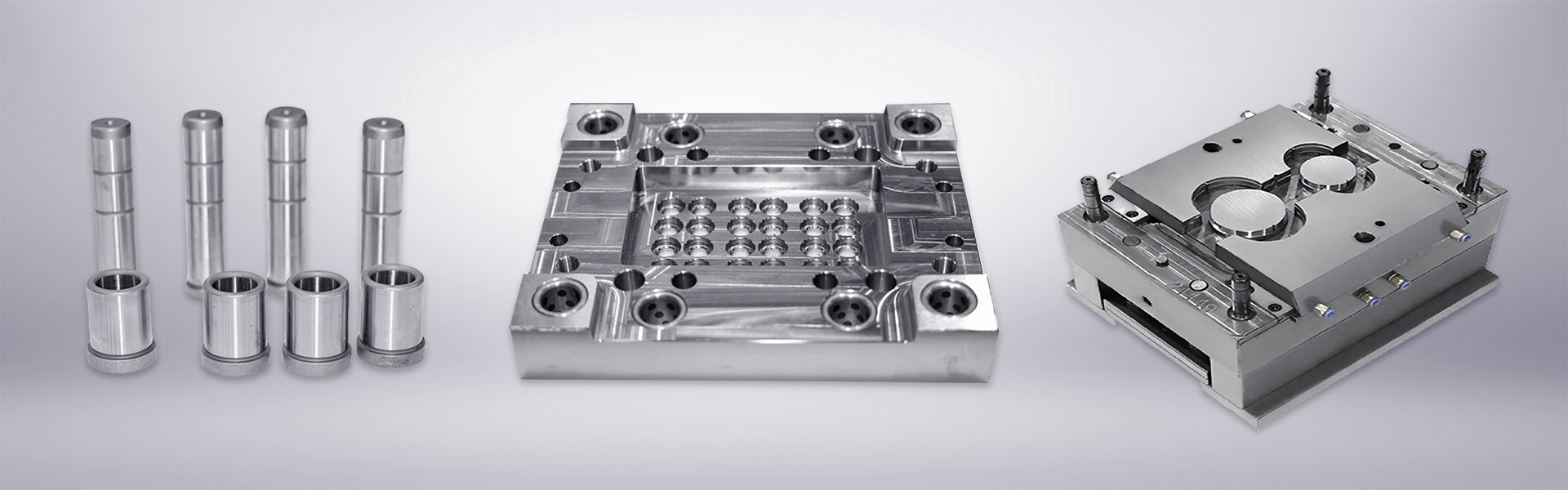

Understanding Metalworking Drill Bits

When selecting a drill bit for metalwork, the first step is identifying the type of metal you will machine—whether aluminium, steel, stainless steel, or hardened alloys. Material hardness impacts wear resistance and heat generation during drilling. We find that China drill bit manufacturers that specify substrate material, coating type (such as TiN or TiAlN), and flute design provide better performance consistency. It is normal to see variations in drilling performance based on bit geometry; for example, split-point designs often reduce walking and improve centering on metal surfaces. Evaluating these specifications upfront, rather than generic labels, helps prevent costly rework and ensures longevity of tools during high-volume production.

How Supplier Selection Matters

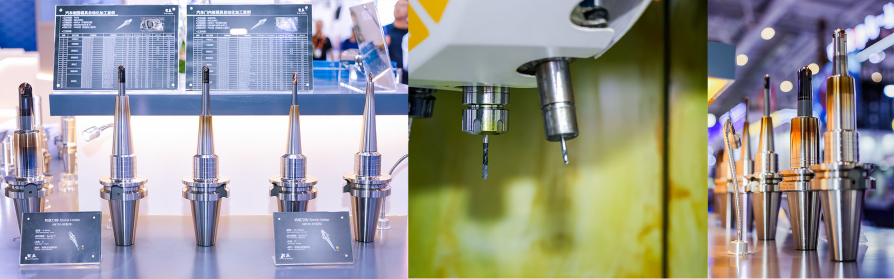

Choosing the right supplier is just as important as choosing the right drill bit. As attendees and contributors at ITES Shenzhen, we connect with global suppliers and advanced material experts, giving our procurement teams firsthand access to established China drill bit manufacturers and their innovative product lines. The Chinese manufacturing ecosystem has matured rapidly, offering both competitive lead times and a wide range of tooling options. Engaging directly with vetted suppliers at exhibitions like ITES China enables us to discuss applications, customization requirements, and quality control processes thoroughly before placing orders. This proactive sourcing approach ensures that our metalworking projects always utilise tools that consistently match performance expectations and production standards.

Advantages of Engaging with ITES Exhibitions

Our presence at ITES Shenzhen reflects our commitment to staying at the forefront of precision manufacturing. The exhibition showcases cutting tools, machine tools, automation systems, and more, creating a comprehensive environment for industry knowledge exchange. At these events, it’s possible to compare different drill bits from Chinese brands side by side and gather technical insights from product presentations and live demos. Well-organised showcase areas allow us to explore metallurgy, bit coatings, and performance feedback directly from designers and engineers. These experiences shape our procurement strategies and help guide partners who are also seeking the best tools for metalworking applications.

Closing Thoughts and Conclusion

Choosing the right drill bits involves understanding material properties, geometry, and supplier capabilities, and at ITES China, we see how these factors intertwine. By working with reputable China drill bit manufacturers and participating in industry events like ITES Shenzhen, we improve our tooling decisions and connect with experts who drive innovation in metalworking. Whether you are refining product specifications or seeking reliable tooling sources, aligning technical evaluation with business intelligence is crucial. Our experience at these exhibitions reinforces why detailed tool selection and supplier engagement are essential parts of successful metalworking projects.