Metal Joining Innovation: Laser Welding, Arc Welding, Resistance Welding, and Automated Solutions

【Introduction】 Metal Joining Innovation: Laser Welding, Arc Welding, Resistance Welding, and Automated Solutions

Metal joining has become a cornerstone of modern manufacturing, particularly in industries like automotive, electronics, and energy storage. At ITES China, we constantly explore innovative techniques to enhance productivity and precision. Among these, laser welding manufacturers provide highly controlled processes that minimize heat distortion while achieving strong joint integrity. By integrating resistance welding and other automated solutions, we can deliver consistent results across complex assemblies, ensuring quality and efficiency. Our experience allows us to guide clients in selecting technologies that meet both current production demands and future scalability.

Understanding Welding Technologies

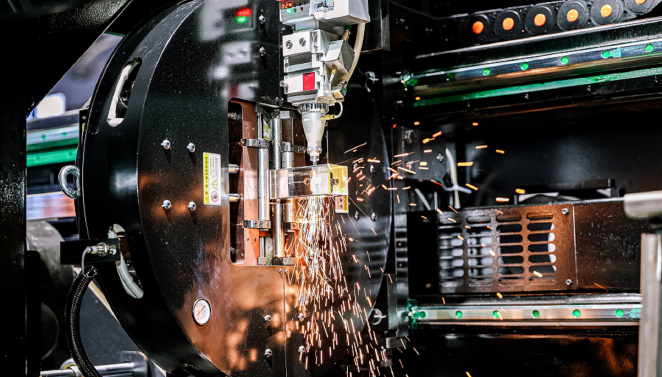

We recognize that different projects demand tailored approaches. Laser welding offers high-speed, precise joining ideal for thin sheets and intricate components. Its ability to focus energy on a narrow zone reduces material deformation and post-processing needs. Meanwhile, arc welding remains indispensable for heavy-duty applications where robust penetration is essential. Our team often combines these methods with resistance welding to achieve hybrid solutions that meet stringent industrial standards. By understanding these technologies, we can advise clients on the most suitable approach for their production lines, balancing speed, strength, and cost. Additionally, our engineers frequently conduct trials to validate parameters and optimize energy efficiency, ensuring that every joint meets durability expectations.

Advantages of Chinese Suppliers and Automated Integration

As a leading organizer of industrial exhibitions, ITES China highlights the capabilities of Chinese suppliers in metal joining. Many of our partners provide complete solutions, from equipment supply to automation integration. Automated resistance welding cells and robotic laser welding systems improve repeatability and reduce labor-intensive steps. This integration allows manufacturers to scale operations without compromising accuracy, particularly in sectors like medical devices, AI servers, and energy storage cabinets. We also emphasize the importance of supplier reliability and after-sales service, which strengthens the overall supply chain for international buyers. Working closely with suppliers ensures timely delivery, flexible customization options, and adherence to global quality standards, making it easier for companies to implement advanced metal joining solutions.

Showcasing Innovations at ITES China

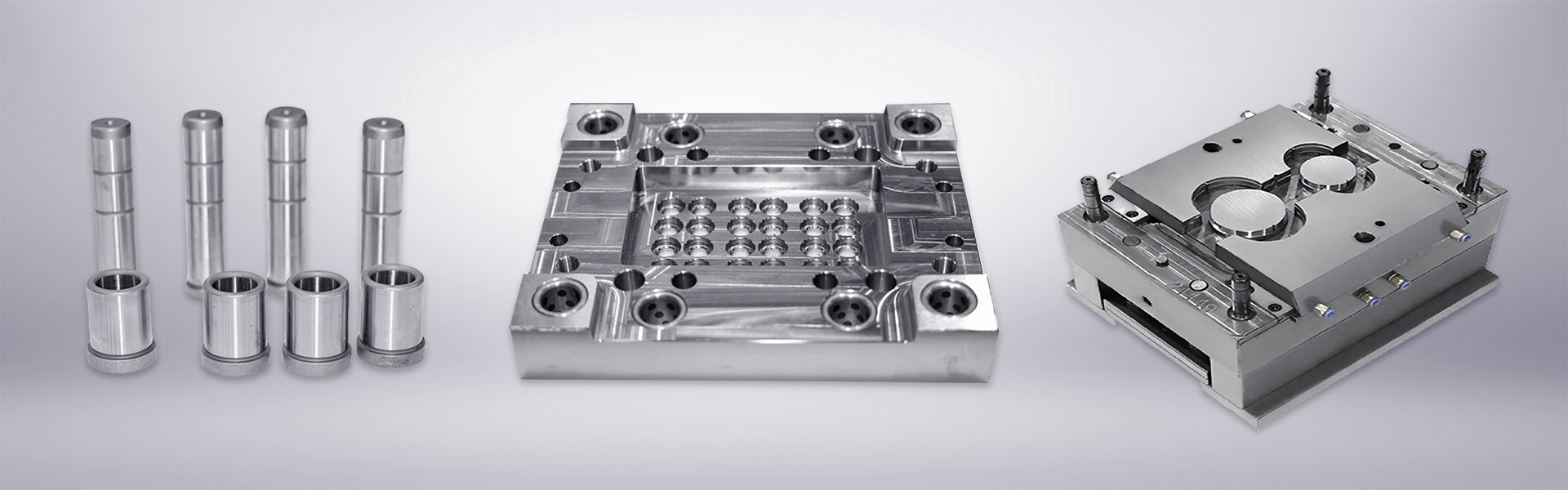

Our upcoming exhibition provides a platform to explore these technologies firsthand. Visitors can experience cutting-edge laser welding manufacturers and automated resistance welding systems designed for high-volume production. Exhibitors will display innovative equipment, including welding robots, precision cutting tools, and flexible production lines. Additionally, attendees can engage with engineers and see demonstrations for applications such as high-precision medical components, AI server chassis, and electric vehicle battery enclosures. The exhibition also offers seminars on process optimization and case studies from leading industrial clients, enabling participants to gain practical insights. This hands-on exposure allows visitors to evaluate new solutions, understand supplier capabilities in depth, and forge valuable partnerships within the metal joining ecosystem.

Conclusion: Advancing Metal Joining Together

At ITES China, we are committed to driving metal joining innovation through knowledge sharing and the showcasing of cutting-edge technologies. By integrating traditional arc welding, advanced laser welding solutions, and resistance welding systems, we help manufacturers achieve higher production efficiency, superior joint quality, and flexible automation capabilities.

Laser welding, with its advantages in precision, speed, and minimal heat input, is increasingly essential for high-value and automated manufacturing scenarios. Together with proven arc welding processes and reliable resistance welding technologies, it forms a comprehensive metal joining ecosystem on display at ITES China.

Our exhibition not only highlights these technological advancements but also connects industry professionals with laser welding manufacturers and system suppliers capable of delivering customized solutions for diverse industrial applications. We invite industry leaders, engineers, and decision-makers to join us at ITES China to explore laser welding innovations, evaluate supplier capabilities, and witness the future of automated metal joining. Through collaboration and continuous innovation, we aim to strengthen the global metal joining ecosystem while providing practical solutions for modern manufacturing challenges.