Force-Control Grinding Heads & Sensors: Enhancing Accuracy in Automated Finishing

【Introduction】 Force-Control Grinding Heads & Sensors: Enhancing Accuracy in Automated Finishing

Achieving consistent, high-quality surface finishes on complex components remains a persistent challenge in automated manufacturing. Variations in material density, casting imperfections, and part tolerances can disrupt processes that rely on rigid, pre-programmed paths. This is where adaptive technologies, specifically force-control grinding heads and sensors, become essential. These systems introduce a sense of touch to robotic cells, allowing for real-time adjustments that ensure uniformity and protect both the tool and the workpiece. For manufacturers seeking reliable automated machining solutions, mastering this technology is a significant step toward higher quality and reduced waste.

The Operational Principle of Adaptive Force Control

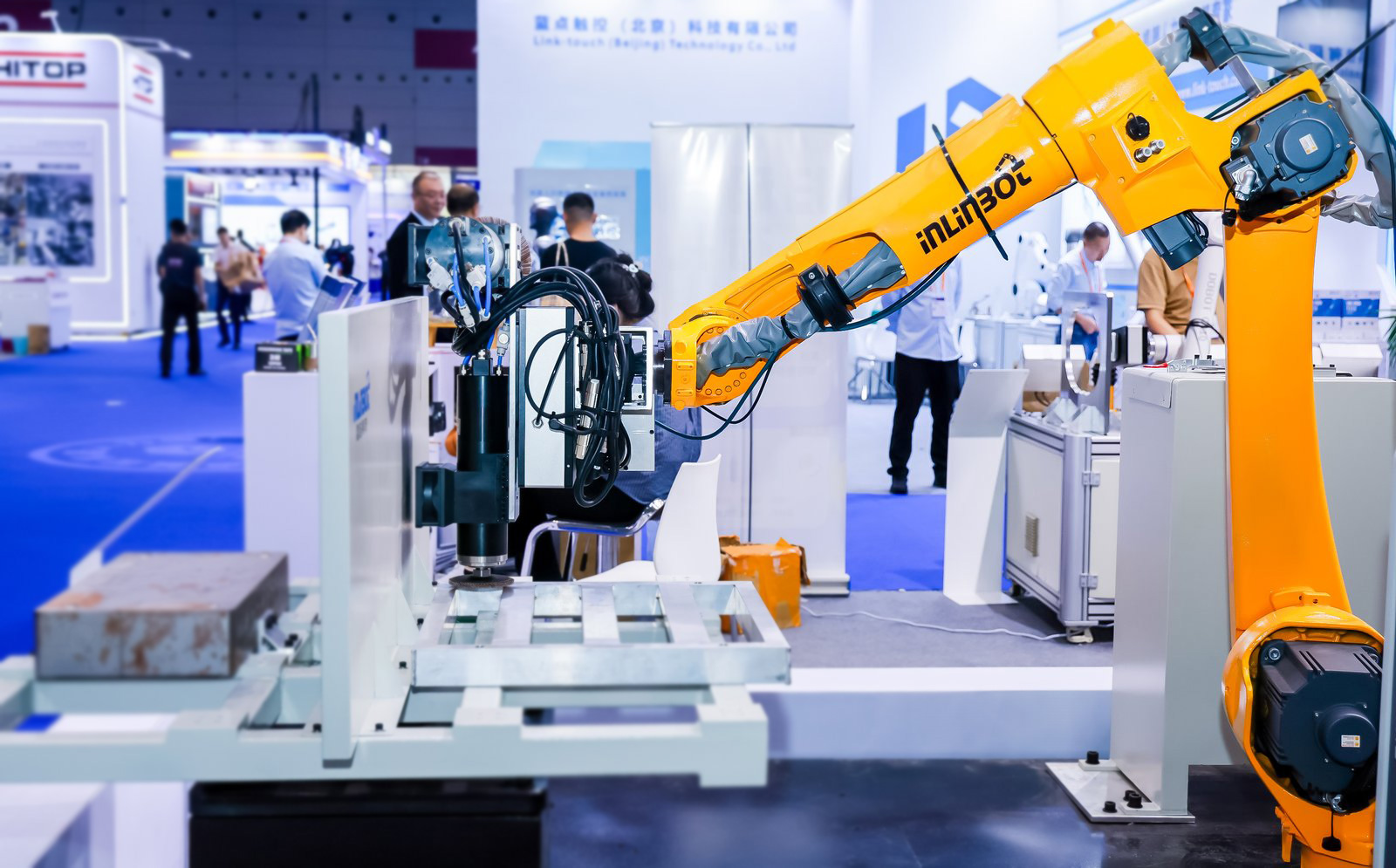

At its core, force-control technology is about closed-loop feedback. A system typically comprises a sensor that measures interaction forces and a compliant grinding head or tool holder that can make micro-adjustments. During a process like polishing a turbine blade or deburring a machined housing, the sensor continuously monitors the applied force. If the programmed path encounters unexpected geometry or a harder material spot, the system instantly compensates by slightly retracting or adjusting the tool position. This maintains a constant, optimal force. This capability transforms a standard robotic arm from a simple position repeater into an intelligent finishing system. It addresses the inherent variability in pre-machined parts, which is a common hurdle in precision machining automation. The result is a finished product that meets stringent specifications without manual intervention or costly rework.

Supply Chain Integration and Manufacturing Ecosystems

The development and integration of these sophisticated systems benefit greatly from a concentrated and collaborative manufacturing ecosystem. Proximity to a vast network of component suppliers, from sensor manufacturers to specialized tooling producers, allows for rapid prototyping and system optimization. This environment enables solution providers to work closely with end-user industries, such as automotive or medical device manufacturing, to develop application-specific automated machining solutions. The ability to source high-quality mechanical components, electronics, and software support within a streamlined supply chain contributes to both the advancement and accessibility of force-control technology. This integrated approach helps in creating robust and cost-effective systems that are crucial for the broader adoption of advanced precision machining automation across global supply chains.

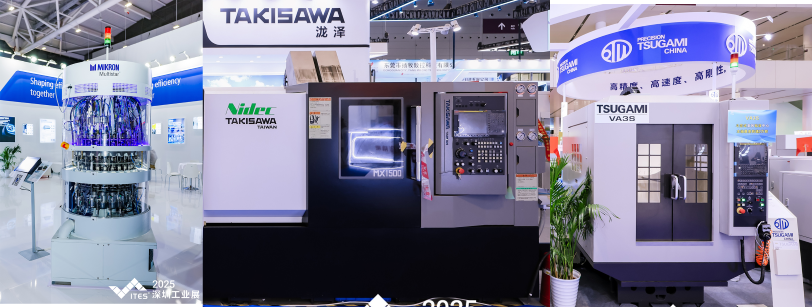

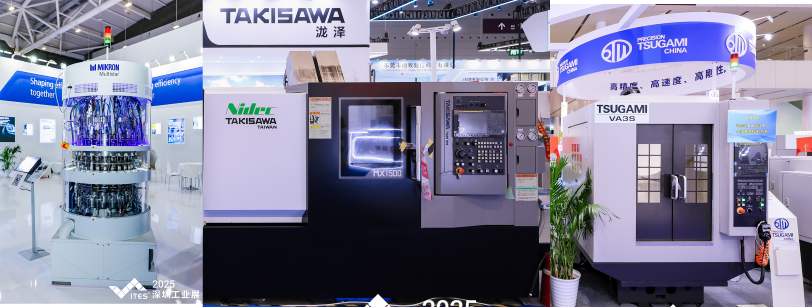

Exploring Advanced Finishing Technologies at Industry Events

For engineers and production managers aiming to implement or upgrade these systems, evaluating the technology firsthand is vital. Industry exhibitions dedicated to advanced manufacturing provide a necessary platform for this exploration. At ITES China, the Precision Machining Automation zone serves as a central point for this discovery. The event gathers a wide spectrum of technology providers, from developers of core force-sensing hardware to integrators of complete robotic finishing cells. Visitors can examine various automated machining solutions in a single venue, comparing different approaches to adaptive grinding, polishing, and deburring. The exhibition scope includes direct demonstrations of force sensors, compliant grinding heads, and the complete range of supporting equipment like automated cleaning stations and coating solutions. Seeing these technologies operate, and discussing specific application challenges with exhibitors, provides practical insights that inform investment and integration decisions.

The move toward more responsive and intelligent manufacturing systems is defined by technologies that bridge the digital and physical worlds. Force-control systems exemplify this shift, bringing essential adaptability to automated finishing tasks. Their development is accelerated within connected industrial ecosystems that foster innovation and practical application. For any organization invested in the next stage of precision machining automation, engaging with the complete landscape of technology and providers is a necessary step. Events like ITES China create that essential junction, where observation, comparison, and technical dialogue converge to support informed decisions and successful implementation of advanced automated machining solutions.