Automation in Surface Finishing: Sandblasting, Shot Blasting, Brushing, and Chemical Deburring

【Introduction】 Automation in Surface Finishing: Sandblasting, Shot Blasting, Brushing, and Chemical Deburring

Surface finishing is often the definitive step that determines a component's performance, longevity, and aesthetic quality. Processes like sandblasting, shot blasting, brushing, and chemical deburring are not merely cosmetic; they influence fatigue resistance, adhesion properties, and assembly fit. As tolerances tighten and volumes increase, executing these processes manually becomes a bottleneck, introducing inconsistency. The strategic implementation of precision machining automation into these finishing stages represents a direct response to this challenge, elevating them from manual operations to controlled, repeatable engineering functions.

Technical Execution of Automated Finishing Processes

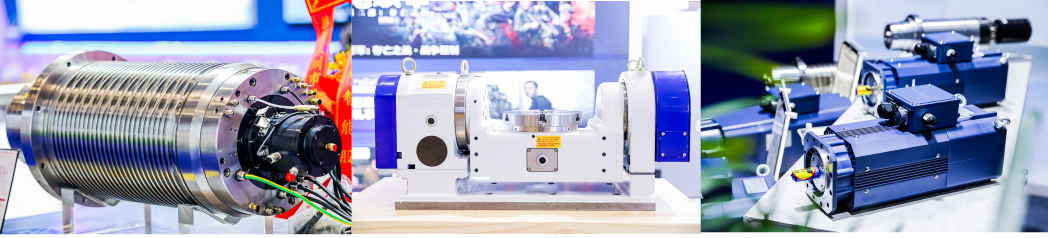

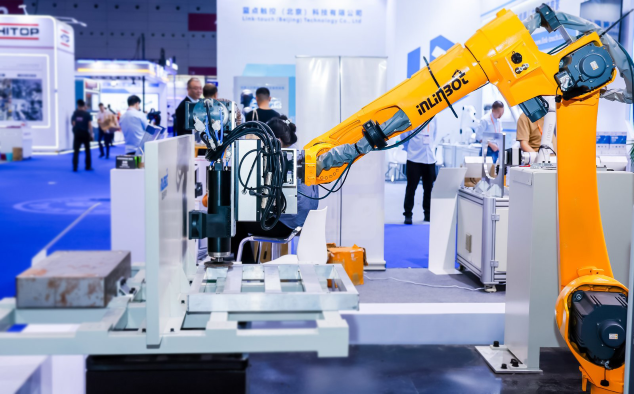

Each finishing method presents unique requirements that automated machining systems are designed to meet with precision. Automated sandblasting and shot blasting cells regulate media flow, pressure, nozzle trajectory, and dwell time with programmatic accuracy, ensuring uniform surface preparation or peening across a full batch. For brushing and polishing, robotic arms equipped with force-controlled tools maintain consistent contact pressure and follow complex contours, eliminating the variability inherent in manual work. Chemical deburring, which relies on precise etchant chemistry and exposure time, benefits greatly from automated handling systems that manage immersion cycles with exact timing and agitation, guaranteeing predictable and complete burr removal. This shift to automation transforms these critical finishing steps into data-driven, reliable segments of the production line.

The Advantage of an Integrated Supplier Network

Successfully deploying these automated solutions depends on more than just a robot; it requires an ecosystem of specialized knowledge. We have observed the growth of a robust supply chain where expertise in mechanical design, process chemistry, robotic integration, and control systems converges. This network enables the development of turnkey cells where the automation hardware, tooling, process media, and safety enclosures are designed cohesively. For manufacturers, this integrated approach reduces project risk and commissioning time. Access to this concentrated supplier base facilitates collaboration, allowing for the customization of automated machining solutions that address specific material and geometric challenges, from delicate medical implants to robust automotive transmissions.

Where Technology is Demonstrated and Sourced: ITES China

Evaluating such integrated automation requires direct engagement with the technology and its creators. The Precision Machining Automation zone at ITES China exists for this purpose. This dedicated segment presents a focused environment to examine the complete progression of post-processing automation. The exhibition scope is extensive, covering everything from robotic grinding and polishing workstations to automated sandblasting, shot blasting, and chemical deburring lines. It also includes supporting technologies like industrial cleaning systems, automated coating solutions, and essential peripherals such as force sensors and simulation software. At ITES China, engineering teams and decision-makers can interact directly with suppliers showcasing these tangible solutions. It provides a forum to discuss specific applications for industries including aerospace, medical devices, semiconductors, and electronics, seeing how precision machining automation is applied to real-world finishing challenges.

The integration of automation into surface finishing is a logical progression for manufacturing seeking higher quality and efficiency. It brings necessary control and repeatability to processes that define a component's end-use characteristics. The development of a sophisticated supplier network supports this transition with increasingly integrated and capable systems. For professionals committed to implementing these advancements, platforms that aggregate and demonstrate these technologies are indispensable. ITES China serves as this central point of convergence, connecting the practical demand for reliable finishing with the automated solutions that make it achievable on the production floor.