Choosing the Right Gantry Machining Center for Large-Scale Precision Manufacturing

【Introduction】 Choosing the Right Gantry Machining Center for Large-Scale Precision Manufacturing

When manufacturers reach a stage where part dimensions or production volumes challenge standard machining capacities, the selection of appropriate equipment becomes a critical strategic decision. The gantry machining center represents a significant category within this high-stakes arena, designed for scenarios demanding substantial work envelopes without sacrificing precision. For operations focused on large housings, molds, or baseplates, understanding this machine tool’s role is the first step toward a sound investment.

Defining the Capabilities and Applications of the Gantry Platform

A gantry type machining center is structurally defined by its overhead bridge-like framework, which carries the spindle mechanism along the X and Y axes over a stationary or moving table. This configuration provides inherent stability and rigidity, essential for managing the cutting forces involved in machining large, heavy workpieces. The primary advantage is the ability to maintain high accuracy over an extended travel range. These machines are fundamental in sectors like aerospace, energy, and heavy equipment manufacturing, where they handle complex contouring on irregular-shaped parts and large-scale plates. The choice often centers on requirements for precision component production that standard vertical or horizontal centers cannot physically accommodate or execute with necessary stability.

Evaluating Supply Chain and Manufacturer Considerations

The global market for these machine tools includes strong capabilities from various regions, with a notable concentration of manufacturers offering competitive propositions. For many international buyers, engaging with this supply ecosystem presents specific advantages. A key consideration is the balance between technical specification, total cost of ownership, and after-sales support. Suppliers have developed extensive experience in tailoring machines for high-efficiency and high-stability machining scenarios. Factors such as local access to technical service, availability of custom options for specific materials or tolerances, and the scalability of support become as important as the initial machine specifications. The decision process involves assessing not just the unit's brochure, but the manufacturer's ability to partner in long-term productivity and integration into an existing workflow.

Leveraging Industry Gatherings for Direct Comparison and Validation

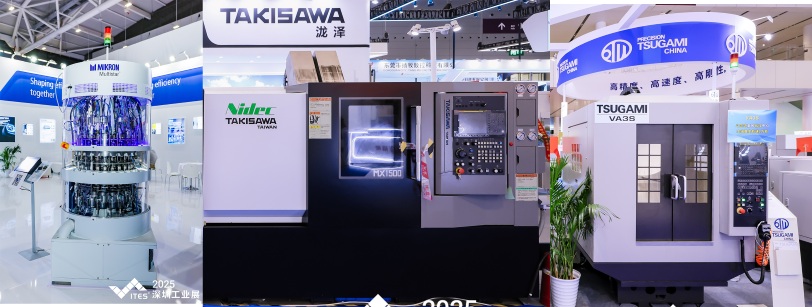

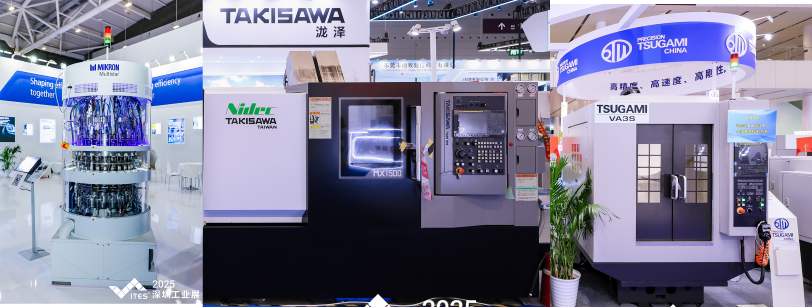

Given the substantial commitment a gantry machining center represents, direct evaluation is irreplaceable. Technical datasheets can only convey a limited perspective on machine performance, build quality, and operational nuance. This is where a specialized industrial platform provides decisive value. At ITES China, the machining center exhibition zone is designed for this exact purpose. It allows production engineers and decision-makers to interact with a concentrated array of technology. The display routinely features live demonstrations of 5-axis machining centers, vertical and horizontal models, alongside the gantry type machining center. Observing these machines in operation, discussing advanced machining technologies and solutions with engineering teams, and comparing the rigidity and construction of different models side-by-side offers a practical assessment no remote channel can match.

The path to selecting capital equipment for large-scale work requires moving from theoretical specifications to tangible verification. Engaging with a knowledgeable supply base is a critical phase, but it must be paired with hands-on inspection. Our event creates that necessary environment. By presenting a focused segment on advanced machining solutions, ITES China enables a direct and efficient evaluation process. It connects those who build these precision tools with those who use them to manufacture critical components, facilitating informed decisions grounded in demonstrated capability and direct technical dialogue.