What to Look for When Sourcing a CNC Machining Center in China: Technology, Specs, and Supplier Evaluation

【Introduction】 What to Look for When Sourcing a CNC Machining Center in China: Technology, Specs, and Supplier Evaluation

Acquiring a CNC machining center represents a substantial capital investment with long-term operational implications. The process extends beyond comparing price lists to a detailed assessment of technological capability, specification alignment, and supplier reliability. For global manufacturing firms, China's market for a China CNC machining center presents a wide array of options, necessitating a structured evaluation framework. We recognize that the decision involves technical, commercial, and logistical considerations that define production outcomes for years. This evaluation forms the foundation for securing equipment that meets precise demands for precision, efficiency, and stability in component manufacturing.

Core Technical Specifications and Application Alignment

The initial phase involves a rigorous analysis of technical specifications against production requirements. Key distinctions arise between machine types, such as the complex contour capabilities of a 5-axis CNC machining center Chinese producers offer versus the high-volume efficiency of a horizontal machining center. Specifications like spindle power, torque, travel distances, positioning accuracy, and repeatability are not mere numbers; they dictate the machine's suitability for machining complex housings, shafts, or plates. Furthermore, the integration of advanced machining technologies, including high-speed milling or advanced thermal compensation, directly affects final part quality and throughput. Defining these parameters clearly narrows the search to machines engineered for specific high-precision scenarios.

Assessing Supplier Capability and Supply Chain Integration

Identifying a capable supplier for a China CNC machining center is as critical as selecting the machine itself. Evaluation should consider the manufacturer's engineering support, documentation quality, and availability of training and spare parts. The regional supply chain advantage in China often allows for more responsive service and shorter lead times for critical components. It is advisable to examine a supplier's project history, seeking evidence of successful installations for applications similar to your own. This due diligence helps verify their experience in delivering not just a machine, but a functional production solution. The strength of a CNC machining center China supply network lies in its depth, offering options from large-scale OEMs to specialized firms focused on particular technologies.

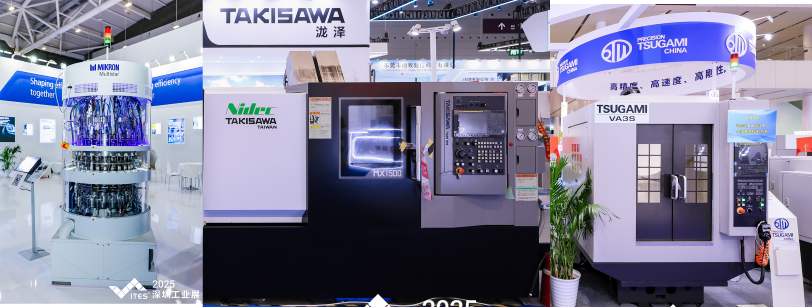

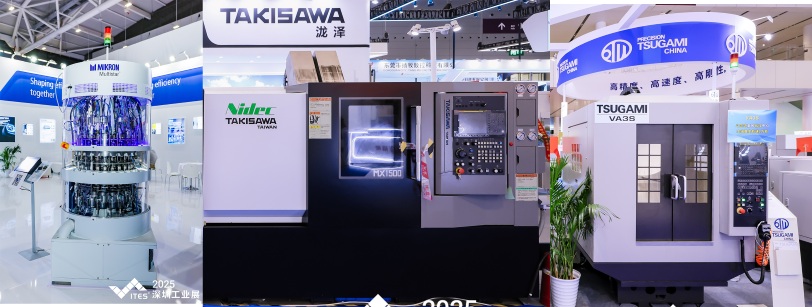

The Value of Direct Inspection at a Focused Industrial Platform

Technical data sheets and supplier claims gain necessary context through physical inspection and operational demonstration. This is where a platform like ITES Shenzhen creates definitive value. Our industrial manufacturing trade fair dedicates significant exhibition space to machining centers, allowing for direct comparison. Attendees can evaluate the build quality, control system interfaces, and actual performance of vertical, horizontal, gantry, and 5-axis models side-by-side. At ITES Shenzhen, the China CNC machining center is not an isolated exhibit; it is displayed within a complete manufacturing ecosystem, surrounded by the CNC systems, tooling, fixturing, and measurement technologies required for its operation.

The exhibition scope at ITES Shenzhen supports a comprehensive sourcing workflow. Beyond the machines, professionals can engage with suppliers of complementary critical technologies: precision cutting tools, tool holders, CMMs, optical measuring systems, and manufacturing software. This integrated view is essential for planning a complete cell or production line. Discussions at the event can cover integration feasibility, potential technical hurdles, and long-term support plans directly with engineering teams. For a CNC machining center China investment, this level of access to both the primary equipment manufacturer and the ancillary technology providers reduces procurement risk.

Sourcing a machining center is a multidimensional process where technical specifications, supplier viability, and real-world performance data must converge. Our role at ITES Shenzhen is to provide the physical and professional environment where this convergence can happen efficiently. The event assembles the relevant technologies and the experts behind them across five structured sub-exhibition areas. For engineering and procurement teams, this access facilitates informed decisions, moving from theoretical evaluation to practical confidence in the equipment and partnerships that will drive their manufacturing operations forward.