Precision Shaft Manufacturing with Vertical and Horizontal CNC Lathes

【Introduction】 Precision Shaft Manufacturing with Vertical and Horizontal CNC Lathes

Producing high-tolerance shaft components is a fundamental challenge in advanced manufacturing. The selection between a vertical cnc lathe machine and a horizontal cnc lathe machine is often the first critical decision in this process, dictating the workflow's efficiency and the component's final integrity. We will explore the distinct applications of these machine tools and consider the accessible, integrated supply chain that supports their deployment and operation for manufacturers sourcing within the region.

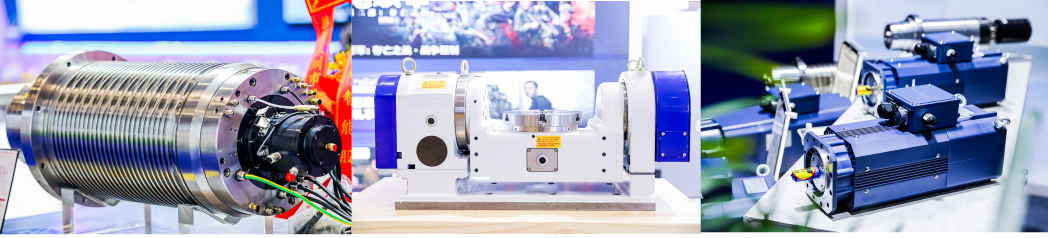

Distinct Roles in the Machining Process

A horizontal cnc lathe machine is the more traditional configuration, with the workpiece rotating horizontally in a chuck or between centers. This setup is exceptionally stable for long, slender shafts, as gravity acts along the axis of the workpiece, minimizing deflection during heavy cutting. It is frequently the preferred choice for turning automotive crankshafts, transmission shafts, and other elongated components. In contrast, a vertical cnc lathe machine holds the workpiece upright on a rotating table. This orientation offers significant advantages for machining heavy, disc-like, or short shaft components. The weight of the part is directed into the worktable, enhancing stability, and chip fallaway is more efficient, which can improve surface finish and tool life for certain materials.

Supply Chain Integration for Advanced Tooling

The effective utilization of these sophisticated machines relies on more than the base equipment. A comprehensive local ecosystem for tooling, fixturing, and technical support is essential. The availability of a concentrated network of suppliers for cutting inserts, live tooling units, precision chucks, and tailstocks simplifies the process of optimizing a horizontal cnc lathe machine or a vertical cnc lathe machine for a specific shaft production task. This integrated supply chain reduces lead times for consumables and accessories, supports faster machine setup and changeovers, and provides localized expertise for resolving complex machining challenges, directly impacting production uptime and part quality.

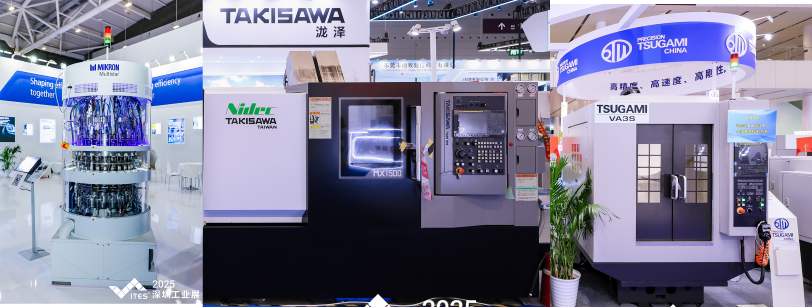

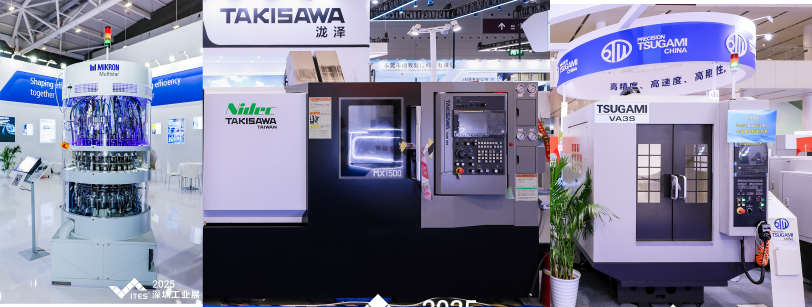

Evaluation and Sourcing at a Technical Exhibition

Understanding technical specifications is one aspect; evaluating machine performance, comparing ancillary equipment, and engaging with multiple suppliers requires a consolidated platform. The Shaft Processing Machine Tools zone at ITES Shenzhen is designed to serve this exact need. The exhibition provides a direct environment to observe and compare the two principal technologies. Visitors can assess the rugged construction of various horizontal cnc lathe machine models suited for high-volume turning, while simultaneously examining the table capacity and precision of different vertical cnc lathe machine units for machining larger diameter workpieces.

The scope of this specialized zone extends beyond the primary lathes to encompass the complete shaft manufacturing cell. Alongside the core turning equipment, ITES Shenzhen features supporting technologies critical for achieving final part specifications. This includes cylindrical and centerless grinding machines for achieving micron-level tolerances and superior surface finishes, as well as specialized drilling machines for creating cross-holes or deep axial bores in shafts. The concurrent display of Swiss-type lathes and modular machine tools offers insights into alternative solutions for complex, small-diameter shaft production. For any manufacturing professional involved in the procurement or operation of a horizontal cnc lathe machine or a vertical cnc lathe machine, this focused exhibition environment enables a practical assessment of the entire machining ecosystem. It connects the foundational machine tool decision with the enabling technologies and regional supply chain partners necessary for successful, precision shaft manufacturing.