How Swiss-type and Turret CNC Lathes Enhance Small and Medium Shaft Production

【Introduction】 How Swiss-type and Turret CNC Lathes Enhance Small and Medium Shaft Production

Manufacturing small to medium-sized shaft components with high repeatability and complex geometries presents distinct challenges. Tolerances for dimensions, form accuracy, and surface roughness are often stringent, especially in fields like automotive or medical device manufacturing. Two specific machine tool architectures have become particularly important for meeting these demands: the Swiss type cnc lathe and the turret cnc lathe. Each offers a unique approach to precision turning, and understanding their operational advantages is key for production engineers aiming to optimize their machining processes for shaft work.

Technical Distinctions and Production Applications

The fundamental difference between these lathes lies in their movement and tooling strategy. A Swiss type cnc lathe is engineered for machining long, slender parts with extreme precision. Its defining feature is a guide bushing that supports the bar stock very close to the cutting tool. The material slides through the bushing while the headstock moves in the Z-axis, and tools arranged radially around the workpiece perform operations. This setup minimizes deflection, allowing for exceptional accuracy on delicate shafts, pins, and connectors. In contrast, a turret cnc lathe typically holds the workpiece stationary or in a rotating chuck while a multi-station tool turret indexes to bring different tools into position. This configuration offers strength and speed for machining shorter shaft components, providing robust cutting capability and efficient tool changes for operations like facing, turning, grooving, and threading. Selecting between them often depends on the part's length-to-diameter ratio and complexity.

Supply Chain Support for Advanced Machine Tool Integration

The effective deployment of these sophisticated machines relies on a supportive and capable supply network. Proximity to a dense ecosystem of technical specialists, from machine tool builders to cutting tool manufacturers and automation integrators, facilitates smoother implementation. This environment allows manufacturers to source not just the machine, but also the ancillary fixtures, tooling packages, and software support needed to configure a Swiss type cnc lathe or a turret cnc lathe for a specific shaft production task. The availability of local technical service and application engineering helps reduce downtime and accelerates the process from installation to full productivity. This integrated support structure is a significant factor for workshops investing in advanced turning capabilities to serve global supply chains requiring high-volume, precision shaft components.

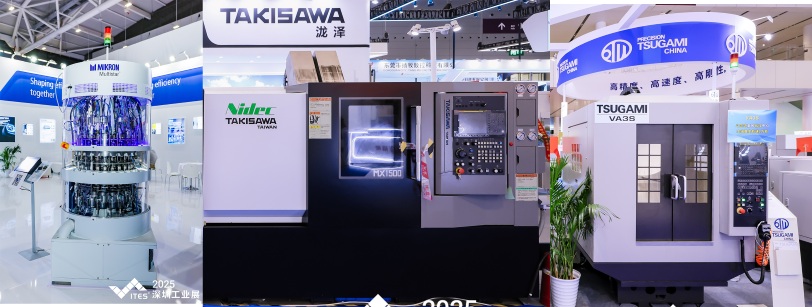

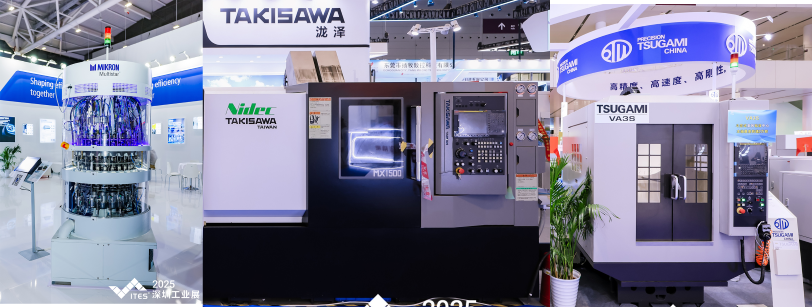

Evaluating Turning Solutions at a Focused Industrial Platform

Choosing the right machining platform requires hands-on evaluation and direct technical discussion. A specialized industrial exhibition provides the optimal environment for this critical assessment. At ITES Shenzhen, the dedicated zone for shaft processing machine tools serves as a central gathering point for this technology. Here, production managers and engineers can directly compare the performance and build quality of various machines. The exhibition scope includes both Swiss type cnc lathe and turret cnc lathe models, allowing for side-by-side observation of their work on sample components. Beyond the primary machines, the zone also features supporting technology such as cylindrical grinding machines and deep hole drilling machines, presenting a complete picture of the shaft production workflow. Engaging with exhibitors at ITES Shenzhen allows for detailed conversations about specific materials, tolerances, and desired throughput, moving from general specifications to applicable, project-ready turret cnc lathe and Swiss type cnc lathe solutions.

The evolution of shaft manufacturing is closely linked to the specialized capabilities of modern CNC lathes. The precise, deflection-controlled environment of a Swiss type cnc lathe and the robust, versatile workflow of a turret cnc lathe each address critical production needs. Implementing these technologies successfully is supported by a comprehensive industrial ecosystem that provides both the hardware and the necessary integration expertise. For any operation focused on improving its shaft production quality and efficiency, a visit to a focused event like ITES Shenzhen offers a direct path to operational insight. It is an opportunity to see machinery in operation, understand the latest tooling developments, and engage with the technical expertise that can help translate machine capability into finished part precision.