Improving Shaft Production Efficiency with Advanced CNC Grinding Machines

【Introduction】 Improving Shaft Production Efficiency with Advanced CNC Grinding Machines

Shaft components form the mechanical backbone of countless assemblies, from automotive transmissions to precision medical devices. Their performance hinges on exacting standards for dimensions, form accuracy, and surface finish. Achieving these standards at scale presents a persistent challenge, where traditional machining reaches its limit. This is the domain where advanced CNC grinding machine manufacturers deliver decisive impact. These systems provide the necessary control to transform raw shaft stock into high-performance components with efficiency and repeatability.

The Critical Function of Precision Grinding in Shaft Manufacturing

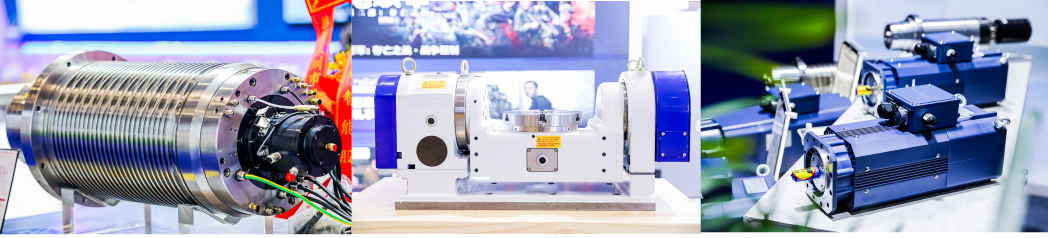

While turning and milling establish basic geometry, the final micron-level accuracy and superior surface integrity of a shaft are typically achieved through grinding. Processes like cylindrical and centerless grinding are indispensable for attaining the tight tolerances on diameter, roundness, and straightness that ensure proper bearing fit and rotational balance. The advancement in machine tool design, spindle technology, and wheel dressing has significantly elevated the capability of modern grinding machines China. Contemporary CNC systems allow for the programming of complex multi-step processes in a single setup. This includes traverse grinding for length, plunge grinding for shoulders, and even contour grinding for specific profiles. This consolidation of operations reduces handling time, minimizes data errors, and directly improves overall equipment effectiveness in shaft production lines.

Capabilities and Integration within the Manufacturing Ecosystem

The progress observed in this sector is supported by a mature and responsive industrial ecosystem. A network of specialized CNC grinding machines manufacturers has developed, focusing not only on the machine tool itself but on total process integration. These suppliers often provide comprehensive application engineering, supporting everything from selecting the optimal grinding wheel and coolant to programming the most efficient cycle. This level of support is crucial for manufacturers adopting new technology. Furthermore, the proximity of this supplier network to a vast market of component producers creates a feedback loop that drives pragmatic innovation. Machines are developed with an understanding of real-world production volumes and material challenges, leading to robust and practical solutions that can be integrated into existing workflows with greater speed.

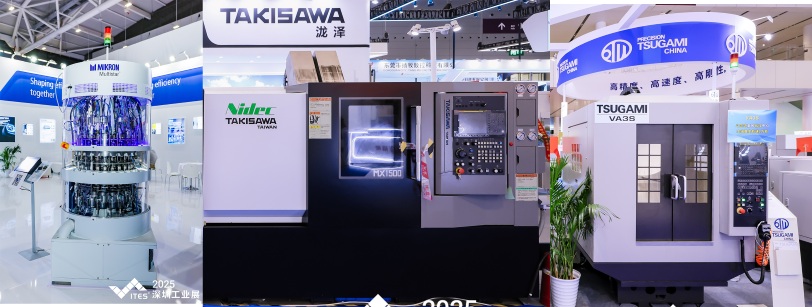

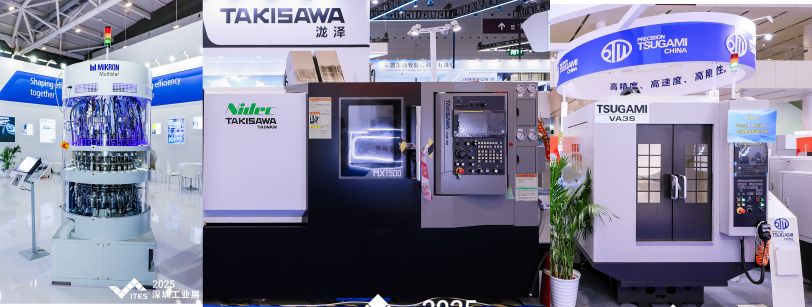

Evaluating Technology at the Dedicated Platform: ITES China

Selecting the right grinding technology requires more than reviewing specifications; it demands hands-on evaluation and direct technical dialogue. The Shaft Processing Machine Tools zone at ITES China is structured to facilitate this critical assessment. This focused area brings together the key technologies for high-precision shaft component production. Visitors can inspect a range of grinding machines China, from high-precision cylindrical grinders to high-throughput centerless systems. The exhibition scope extends to the complete machining chain, including CNC lathes, Swiss-type lathes, and specialized drilling equipment, providing context for where grinding fits into the entire process. At ITES China, engineers and production managers can engage with the technical teams from various CNC grinding machine manufacturers, discussing specific challenges related to material, batch size, and quality requirements. It is a platform to compare methodologies, see live demonstrations, and evaluate how different machines address the core objectives of improving precision and throughput.

The pursuit of higher shaft production efficiency is fundamentally linked to the capabilities of finishing technology. Advanced CNC grinding delivers the precision and process stability required for modern, high-value components. The concentration of engineering expertise and manufacturing depth provides a strong foundation for sourcing and implementing these technologies. For professionals tasked with capital investment decisions, platforms that aggregate and demonstrate these advanced machine tools offer a necessary resource. ITES China provides this concentrated environment, connecting manufacturing challenges with the practical, advanced solutions offered by a wide spectrum of equipment providers. It allows for informed evaluation, ensuring that investments in new grinding capacity directly address the goals of enhanced quality and productivity.