Vertical Drilling Machines and Deep Hole Drilling for Automotive Shafts

【Introduction】 Vertical Drilling Machines and Deep Hole Drilling for Automotive Shafts

Automotive shaft manufacturing presents a distinct set of production challenges, where component integrity directly correlates with vehicle performance and longevity. Achieving the necessary dimensional accuracy, form consistency, and surface finish on these cylindrical parts depends on specialized machining processes. Within this framework, the vertical drilling machine and specialized deep hole drilling machines serve as fundamental technologies. We observe their critical application in creating precise boreholes, oil channels, and mounting points that are standard in transmissions, engines, and drive systems.

The Role of Vertical Drilling in Shaft Production

The vertical drilling machine offers a configuration where the spindle axis is aligned vertically to the worktable. This setup provides significant stability and alignment accuracy, which is crucial when drilling bolt holes or cross passages in automotive shafts. For components like camshafts or gearbox shafts, the perpendicularity of these features to the main axis is non-negotiable. The rigidity of a well-engineered vertical drilling machine minimizes deflection during the cut, ensuring hole straightness and positional accuracy. This capability supports the high-volume, repeatable production environment of the automotive sector, where each operation must maintain strict tolerances for surface roughness and location across thousands of parts.

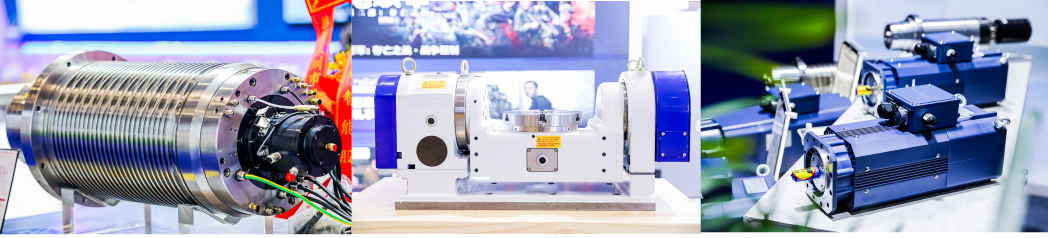

Addressing Complex Internal Geometries with Deep Hole Drilling

When the application requires holes with a depth many times greater than their diameter—such as for lubrication channels in crankshafts or hollow passages for weight reduction in drive shafts—standard drilling reaches its limit. This is the domain of deep hole drilling machines. These specialized units employ specific techniques, like gun drilling or BTA drilling, to effectively evacuate chips and manage heat generation over extended tool travel. The process is engineered for scenarios demanding exceptional straightness, surface finish, and diameter control in deep internal features. For automotive engineers, selecting the appropriate deep hole drilling machines technology is a vital step in ensuring the functional reliability and durability of the final shaft component under dynamic loads.

Connecting with Advanced Technology and Supply Chain Solutions

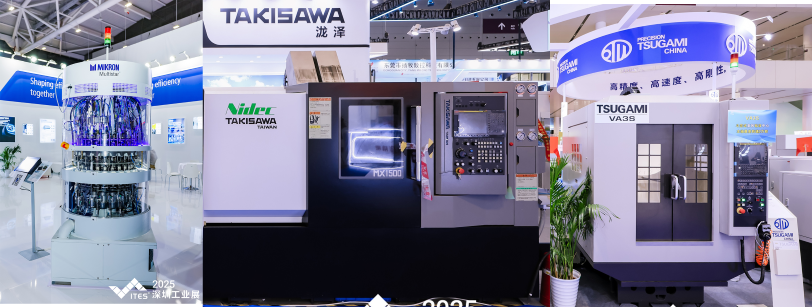

The decision to integrate such equipment involves evaluating not only the machine's specifications but also the broader support ecosystem. Manufacturers seeking these solutions benefit from engaging with a concentrated supply network that understands the stringent requirements of automotive component production. This network extends beyond the machine builder to include tooling specialists, automation integrators, and process engineers. For a comprehensive evaluation, direct engagement with this technical community is invaluable. This is a primary reason professionals visit events like our own. The Shaft Processing Machine Tools zone at ITES China is dedicated to this precise field. The exhibition scope includes a focused display of vertical drilling machines and deep hole drilling machines units alongside other critical technology like CNC lathes and grinding machines. This gathering serves industries from automotive to aerospace, providing a platform for side-by-side comparison.

Attending such a specialized zone allows for practical assessment. Engineers can witness live demonstrations, discuss specific challenges—such as optimizing cycle times for crankshafts or improving the form accuracy of transmission shafts—directly with equipment designers, and explore integrated solutions. Seeing a vertical drilling machine configured for a specific shaft family, or understanding the tooling strategy of a deep hole drilling machines system, provides insights that inform critical procurement and process planning decisions. This direct access to innovation and expertise underscores the functional value of a targeted industrial platform like ITES China for advancing manufacturing capabilities.