AGV vs. AMR: Which Automated Transport Solution Fits Your Factory?

【Introduction】 AGV vs. AMR: Which Automated Transport Solution Fits Your Factory?

As ITES China continues to highlight industrial innovation, we often receive inquiries about the distinctions between automated guided vehicles and autonomous mobile robots. Efficient material transport has become a cornerstone of modern manufacturing, impacting productivity, cost efficiency, and workflow safety. Automated guided vehicles (AGVs) operate on predetermined paths, such as magnetic strips or laser-guided tracks, offering predictable and repeatable motion for high-volume operations. In contrast, autonomous mobile robots (AMRs) rely on sensors, cameras, and artificial intelligence to navigate dynamically, adapting to changes in factory layouts or unexpected obstacles. By understanding these differences, manufacturers can align their transport solutions with operational demands and long-term automation strategies.

Understanding AGV and AMR Capabilities

At our company, we recognize that choosing the right transport solution depends heavily on production type and factory design. Automated guided vehicles are highly effective in structured environments where repetitive tasks dominate, such as moving pallets between fixed stations. They provide reliable throughput, minimal downtime, and consistent handling of materials without frequent human intervention. Conversely, autonomous mobile robots shine in dynamic or complex production lines where flexibility is required. These robots can optimize routes in real time, avoid obstacles, and handle variations in workflow. By deploying AMRs, factories can respond quickly to changing production requirements, integrate with multiple workstations, and reduce errors associated with manual transport processes. Both systems can improve safety, reduce labor costs, and enable more predictable production cycles.

Advantages of Chinese Suppliers and ITES Shenzhen

We have seen that Chinese suppliers, especially those participating in ITES Shenzhen, offer a wide array of automated guided vehicles and autonomous mobile robots tailored for diverse industries. Their supply chain advantages include cost-effective production, quick prototyping, and strong vertical integration. Many suppliers provide scalable solutions, allowing factories to start with a few units and expand gradually. Additionally, local manufacturing ensures timely delivery, easy customization, and rapid technical support. At ITES Shenzhen, visitors can meet these suppliers directly, compare specifications, and discuss integration strategies. This event emphasizes practical solutions while providing insight into regional innovation and global competitiveness in industrial automation.

Exhibition Highlights and Practical Insights

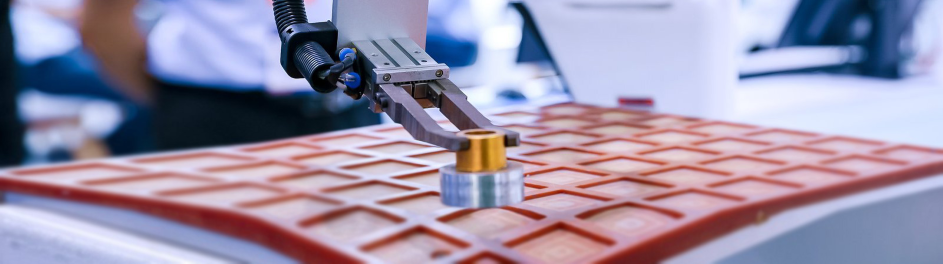

ITES Shenzhen serves as a key platform for manufacturers to explore the latest advancements in material handling. Exhibits feature smart conveyor systems, flexible loading/unloading stations, and advanced robotics platforms. Attendees can observe real-world applications of both automated guided vehicles and autonomous mobile robots, including their role in warehouse management, assembly lines, and mixed-production environments. By attending, our visitors gain valuable knowledge about how to optimize efficiency, reduce operational bottlenecks, and improve workplace safety. Industry experts also provide demonstrations and consultations, helping manufacturers understand which transport solutions align best with their unique operational needs.

Conclusion: Making Informed Automation Choices

Choosing between automated guided vehicles and autonomous mobile robots requires a clear understanding of production goals, factory layout, and workflow complexity. At ITES China, we emphasize the importance of evaluating both options objectively, considering factors such as route predictability, operational flexibility, and supplier support. Participating in ITES Shenzhen allows manufacturers to interact with leading solution providers, gain hands-on experience, and make informed decisions that enhance efficiency and scalability. By integrating the right transport system, factories can achieve improved productivity, adaptable operations, and sustainable growth in their automation journey.