Inspection and Metrology Equipment for High-Precision Components: What You Need to Know

【Introduction】 Inspection and Metrology Equipment for High-Precision Components: What You Need to Know

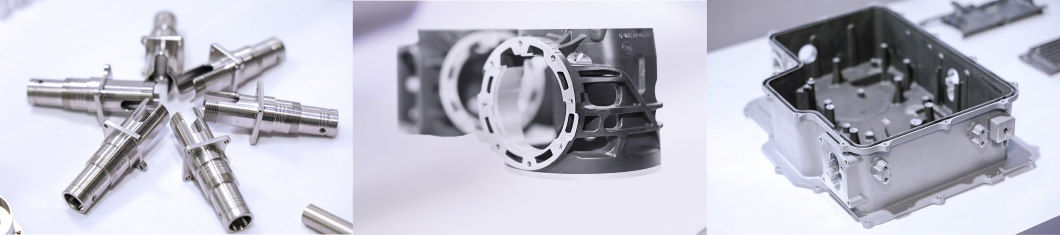

High-precision components are the backbone of modern industries, from medical devices to aerospace machinery. At ITES China, we understand the critical importance of accuracy, consistency, and traceability when it comes to component manufacturing. High-precision components require not only advanced production techniques but also robust inspection and metrology equipment to ensure that every piece meets stringent specifications. As a hub for precision component machining, our exhibition highlights the latest technologies and solutions from top Chinese suppliers, showcasing both innovative machinery and best practices in quality assurance.

Importance of Accurate Measurement in Precision Machining

Reliable inspection and metrology equipment is essential for verifying dimensions, tolerances, and surface quality of complex parts. We collaborate closely with precision machining component suppliers to integrate automated inspection systems into the production workflow. These instruments, including coordinate measuring machines (CMM), optical scanners, and non-destructive testing devices, help manufacturers detect deviations early and maintain consistent quality. Our company emphasizes how precise measurement not only reduces waste but also improves production efficiency, ensuring that components meet both domestic and international standards. Regular calibration and data-driven quality monitoring further strengthen manufacturing reliability.

Advantages of Sourcing from Chinese Suppliers

China has emerged as a leading hub for precision component machining due to its mature supply chains and technological advancements. By partnering with local precision machining component suppliers, we can access a wide range of materials, from specialty metals to advanced alloys, while benefiting from cost-effective production and short lead times. Our platform allows buyers to explore diverse manufacturing methods, including CNC milling, turning, and advanced surface treatment technologies. Additionally, Chinese suppliers often provide end-to-end solutions, from CAD/CAM design to final quality verification, simplifying procurement and accelerating time-to-market for high-precision components. This combination of technical expertise and supply chain flexibility gives our customers a distinct advantage in complex projects.

ITES China Exhibition Highlights

The upcoming ITES China exhibition showcases a comprehensive lineup of inspection and metrology equipment alongside precision component manufacturing modules. Attendees will experience live demonstrations of automated measurement systems, surface treatment technologies, and advanced machining tools. Exhibitors include leading Chinese manufacturers specializing in automotive, medical, aerospace, and semiconductor components. Our event also emphasizes networking opportunities, enabling industry professionals to connect with suppliers, learn about emerging technologies, and explore solutions tailored to their specific production needs. By visiting the exhibition, decision-makers can directly assess product capabilities, witness hands-on demonstrations, and establish partnerships that enhance manufacturing accuracy and efficiency.

Ensuring Precision and Quality in Manufacturing

At ITES China, we believe that reliable inspection and metrology equipment is integral to high-precision manufacturing. By working with experienced precision machining component suppliers, companies can achieve consistent quality, reduce production risks, and stay competitive in global markets. The exhibition not only provides a platform to discover advanced technologies but also fosters collaboration between international buyers and Chinese manufacturers. We invite all professionals involved in precision component production to join us, explore innovative solutions, deepen supply chain connections, gain practical insights from live demonstrations and technical workshops, understand emerging trends in precision measurement, and strengthen overall quality management for superior product outcomes across diverse industrial applications.