Precision Machining for High-Demand Industries: Automotive & Medical

【Introduction】 Precision Machining for High-Demand Industries: Automotive & Medical

Precision machining plays a critical role in meeting the evolving performance and safety demands of complex sectors like automotive and medical manufacturing. At ITES China, we have witnessed how exacting standards in part accuracy, surface quality, and dimensional control directly influence product reliability, operational efficiency, and lifecycle performance. In industries where tolerances are measured in microns, the ability to consistently produce high-quality components is no longer an option — it is a requirement. Leveraging advanced machining platforms, specialized tooling, and deep process expertise, our teams have supported customers in navigating intricate part geometries and the strict compliance requirements of both automotive and medical markets, ensuring both functional performance and regulatory alignment. Additionally, we focus on integrating material selection strategies and thermal management considerations, which are often critical in high-stress applications, further reinforcing our commitment to precision and durability.

Mastering Automotive and Medical Precision

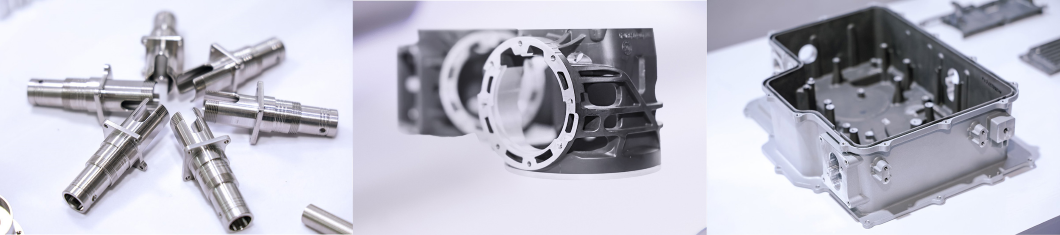

As automotive systems become ever more integrated with electronics, sensors, and electrified powertrains, the demand for precision automotive components continues to rise. These parts — from transmission interfaces to complex housings, electronic module enclosures, and sensor mounts — must deliver exacting fit, durability, and function under dynamic loads and extreme conditions. At the same time, the medical industry’s push toward minimally invasive devices, robotic-assisted surgery, and high-performance diagnostic equipment necessitates medical precision components that combine material biocompatibility with exceptional dimensional accuracy. In both contexts, our approach centers on process stability, meticulous inspection regimes, and collaboration across design, engineering, and manufacturing stages. Working within global supply chains, we emphasize traceable quality control, proactive risk mitigation, and robust documentation practices that align with industry-specific standards and certifications. By focusing on both micro-level precision and macro-level reliability, we help customers reduce variability, enhance patient safety, and improve overall system performance.

Supply Chain Synergies and Industry Insights

Operating within the ecosystem highlighted by ITES Shenzhen, we observe unique opportunities to accelerate supply chain responsiveness, knowledge sharing, and technological innovation. The ITES Shenzhen industrial exhibition brings together advanced machine tools, automation technologies, and precision part specialists from around the world, showcasing solutions that strengthen manufacturing linkages for automotive and medical sectors alike. Participants benefit from integrated displays of metal cutting, surface finishing, inspection systems, additive manufacturing demonstrations, and in-line measurement technologies that help reduce cycle times, improve quality consistency, and optimize production workflows. For companies focused on performance, compliance, and sustainability, this platform emphasizes the value of collaborative ecosystems and shared best practices. Moreover, visitors can engage directly with global suppliers, attend technical seminars, and experience live demonstrations of next-generation machining strategies — providing actionable insights that help translate emerging technologies into practical manufacturing improvements.

Advancing Capabilities Through Integrated Solutions

At ITES China, we continuously refine our capabilities to support complex component requirements. By combining automated production processes, advanced material handling, and adaptive machining strategies, we ensure that both precision automotive components and medical precision components meet demanding standards. Our company also invests in cross-disciplinary training, quality analytics, and feedback-driven process optimization, which strengthens our supply chain’s ability to respond rapidly to design changes or urgent production needs. This integration of technology, expertise, and workflow management enables us to maintain consistent quality while delivering value across every stage of component development. Through these efforts, we can provide our customers with practical solutions that meet stringent performance criteria while remaining efficient and cost-conscious.

Driving Quality and Innovation Through Precision

Ultimately, precision machining is a cornerstone of quality, innovation, and competitiveness in the automotive and medical industries. Our experience at ITES China demonstrates how strategic investment in capabilities, modern equipment, and continuous improvement practices drives measurable impact across product lines. By integrating technical expertise, process control, and industry knowledge, we are better positioned to support customers tackling the toughest part-making challenges. Looking ahead, platforms like ITES Shenzhen will continue to serve as pivotal venues for technology exchange, supply chain partnerships, and knowledge growth — advancing both the precision parts we produce and the industries we serve. Through these efforts, our company fosters collaboration, promotes practical solutions, and contributes to operational efficiency, product reliability, and innovation across demanding applications in high-performance sectors.