From Raw Material to Finished Part: End-to-End Workflow in Precision Component Manufacturing

【Introduction】 From Raw Material to Finished Part: End-to-End Workflow in Precision Component Manufacturing

At ITES China, we believe that high-quality precision component machining begins long before any cutting tool touches a workpiece. The journey starts with selecting the right raw materials, often metals or engineered polymers, that meet stringent mechanical and chemical specifications. In this stage, our engineers assess material properties such as tensile strength, hardness, and corrosion resistance to ensure suitability for the intended application. As one of the precision machining component suppliers ITES Shenzhen relies on, we emphasize that proper material selection reduces the risk of defects and enhances overall performance. From aluminum and stainless steel to specialty alloys, we work closely with trusted material vendors to source inputs that support repeatable results.

Core Production: From Setup to Machining

After raw materials pass inspection, we enter the core precision component machining phase, where parts begin to take shape. We start by programming CNC machines according to detailed engineering drawings, ensuring every axis movement aligns with design intent. Our technicians set up fixtures and tooling, paying special attention to factors like chip evacuation and heat dissipation that influence final accuracy. This machine setup stage is often underestimated in the broader supply chain, yet it is a key differentiator for companies like ITES China that deliver reliability.

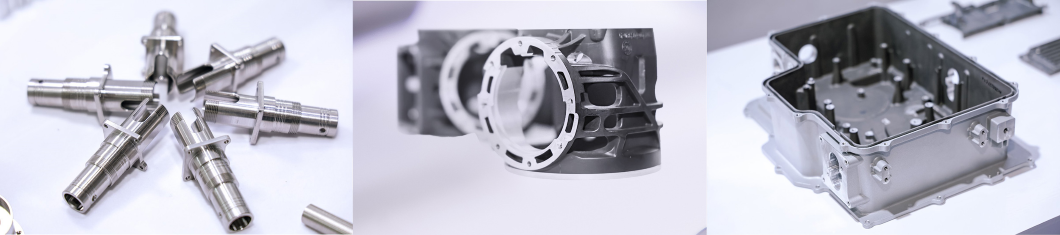

During machining, sophisticated equipment performs operations such as turning, milling, boring, and threading. We monitor cycle times and tool wear closely, adjusting parameters when necessary to maintain dimensional stability within microns. For more complex parts, multi-axis machining centers allow simultaneous cuts on several planes, reducing handling and enhancing precision. Our team’s experience as precision machining component suppliers at ITES Shenzhen means we can balance process speed with product integrity. Finished components from this stage are carefully deburred and cleaned to prepare them for inspection.

Inspection and Finishing: Ensuring Fit, Form, and Function

Inspection is an integral part of our end-to-end workflow at ITES China. After machining, each part undergoes a rigorous series of checks using coordinate measuring machines (CMMs), optical comparators, and surface finish testers. These tools ensure that every dimension, angle, and surface quality characteristic falls within specified tolerances. For critical applications, visual inspection may be augmented with nondestructive testing (NDT) techniques to detect subsurface flaws that are invisible to the naked eye. These steps reflect our commitment as precision machining component suppliers ITES Shenzhen to deliver parts that function reliably in their final assemblies.

Once inspection is complete, components may receive secondary processes such as heat treatment, plating, or anodizing, depending on customer requirements. Packaging and documentation follow, ensuring traceability and protection during shipping. By closing the loop on quality control, we help our clients mitigate risks associated with field failures and costly rework. Customers often tell us that our attention to inspection and finishing is why they partner with ITES China for complex and high-volume precision parts.

Conclusion: Bridging Knowledge and Execution for Manufacturing Success

As we reflect on the precision component machining workflow from raw material to finished part, it is clear that success requires a holistic and disciplined approach. At ITES China, we integrate material expertise, advanced machining, and thorough inspection to provide value far beyond basic manufacturing. Our role among precision machining component suppliers in ITES Shenzhen means we constantly adapt to evolving industry demands, driving efficiency without compromising quality. Looking ahead to events like our upcoming trade show participation, we plan to highlight innovations in equipment and process optimization. Visitors can explore how we apply digital simulation, adaptive machining strategies, and lean principles to support smarter production. By sharing our knowledge and engaging with partners and customers, we aim to elevate understanding of precision manufacturing and strengthen the supply chain for all stakeholders involved.