Inspection and Measurement Equipment for Mold Quality Assurance

【Introduction】 Inspection and Measurement Equipment for Mold Quality Assurance

Ensuring consistent quality in mold production is essential for any precision mold manufacturer. At ITES China, we recognize that precision in design and production begins with reliable inspection and measurement equipment. High-accuracy tools such as coordinate measuring machines (CMMs), surface roughness testers, and 3D optical scanners allow our engineers to evaluate molds at every stage of manufacturing. By implementing these systems, we minimize deviations and enhance the overall performance of molds, ultimately supporting our clients’ end-product reliability. The growing complexity of modern molds makes such equipment indispensable, especially for components with intricate geometries or tight tolerances. Our experience shows that early detection of dimensional inconsistencies significantly reduces production delays and ensures that molds meet both domestic and international standards.

Advancing Quality Through Precision Tools

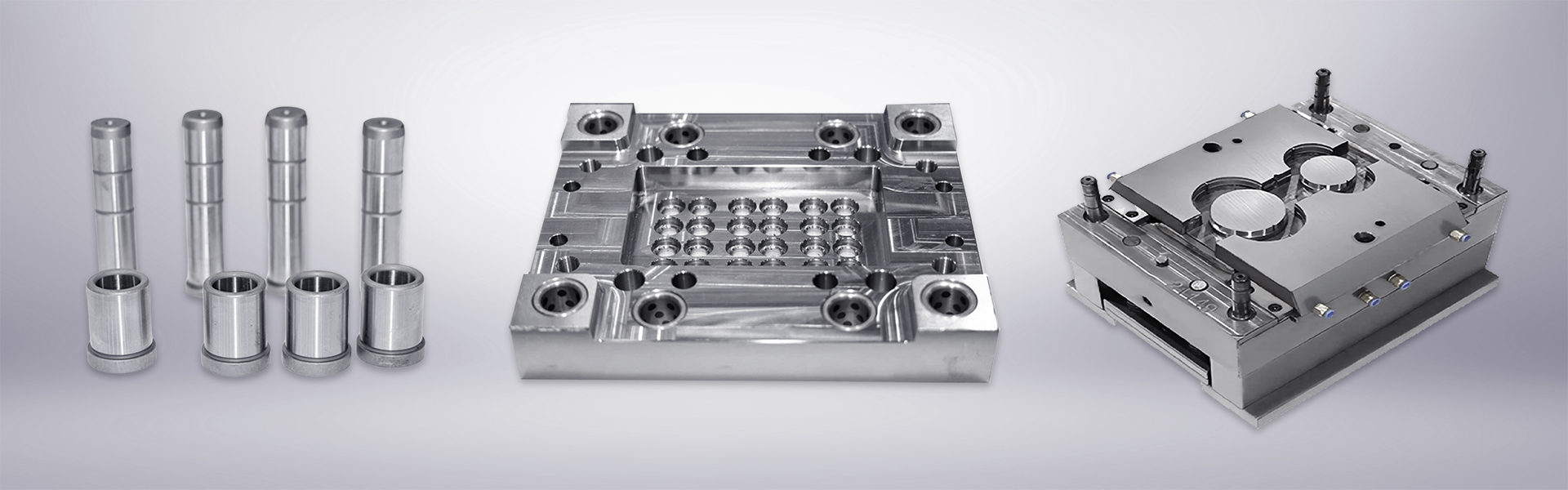

As a leading precision mold manufacturing provider, we integrate advanced inspection technologies into our workflow. Equipment such as laser scanning systems and automated vision inspection ensures that each component meets stringent tolerances. For instance, mold bases, inserts, and ejector pins are verified against precise CAD models to maintain uniformity across batches. Our team at ITES Shenzhen emphasizes the importance of combining automated measurement with expert judgment to detect potential defects early, reducing costly rework and material waste. In addition, we conduct periodic calibration and verification of our instruments, ensuring that every reading reflects the true dimensions and surface quality of the mold. We also train our staff to interpret measurement data accurately, turning technical insights into actionable production adjustments.

The Role of Digitalization in Mold Assurance

Digital solutions complement physical measurement techniques. At ITES China, we utilize CAD/CAE software, digital twin machining systems, and intelligent tool management platforms to monitor mold production in real time. These digital tools help track dimensional accuracy and surface finish, enabling predictive maintenance and continuous improvement. By integrating data from both manual inspections and automated devices, our company creates a comprehensive quality control framework. This approach allows us to respond swiftly to deviations, optimize production workflows, and maintain consistent standards across different mold types and production lines. Moreover, digital documentation ensures traceability, which is critical for clients seeking compliance with rigorous international quality certifications.

Driving Supply Chain Efficiency

By leveraging comprehensive inspection and measurement equipment, precision mold manufacturers in China can offer shorter lead times and higher reliability. The supply chain benefits significantly from reduced errors and faster validation processes. At ITES Shenzhen, our exhibition showcases a wide range of mold types, components, and auxiliary equipment. Visitors can explore solutions for injection, extrusion, stamping, and die-casting molds, as well as coatings, thermochemical treatments, and maintenance consumables. Exhibitors demonstrate innovations in surface treatment technologies, CAD/CAM integration, and automated monitoring systems, reflecting the strengths of China’s industrial ecosystem. Attendees gain insights into how Chinese suppliers can meet global standards while maintaining cost-effective and scalable production. Networking with manufacturers and observing live demonstrations also helps companies identify opportunities to improve efficiency and reduce operational risks.

Ensuring Reliability in Mold Production

Inspection and measurement technologies are pivotal in achieving consistent mold quality. At ITES China, we combine advanced equipment, digital monitoring, and professional expertise to support precision mold manufacturers in delivering reliable and high-performance molds. Attending ITES Shenzhen offers industry professionals the opportunity to engage with leading suppliers, discover innovative inspection solutions, and explore a comprehensive range of mold products. By embracing these tools and technologies, we continue to advance the standards of precision mold manufacturing in China, helping customers achieve both operational efficiency and product excellence in a competitive market. Our commitment to continuous innovation ensures that every mold we deliver contributes to higher productivity, lower defect rates, and long-term client satisfaction.