Smart Warehousing Integration: From AS/RS to WMS & WCS Coordination

【Introduction】 Smart Warehousing Integration: From AS/RS to WMS & WCS Coordination

Modern manufacturing efficiency extends beyond the production floor to the flow of materials that feed and store its output. The coordination between physical storage hardware and the software that governs it defines a facility's logistical capability. We observe that a truly effective integrated warehousing solution functions as a cohesive system, where Automated Storage and Retrieval Systems (AS/RS), Warehouse Management Software (WMS), and Warehouse Control Systems (WCS) operate in concert. This synergy is fundamental for supporting high-mix, low-volume production scenarios and managing complex material flows.

The Hardware Foundation: Automated Storage and Retrieval Systems

The physical layer of a smart warehouse is built upon automated hardware. An AS/RS, which may include stacker cranes and high-density racking, provides the mechanical means to store and retrieve goods without manual intervention. This equipment maximizes vertical space utilization and brings deterministic speed to material handling. However, these systems require precise instructions. This is where the concept of an integrated warehousing solution begins, as the machinery must receive commands from a higher-level control system. The reliability of this hardware layer sets the performance ceiling for the entire storage operation, impacting throughput in raw material supply and finished goods handling.

The Software Brains: WMS and WCS Defined and Differentiated

The intelligence of the warehouse resides in its software, specifically the distinct but interconnected roles of WMS and WCS. A WMS operates at the planning level. It manages inventory data, processes orders, optimizes storage locations based on logic, and generates broad work orders. Think of it as the strategic commander. The WCS acts as the tactical controller. It receives tasks from the WMS and translates them into real-time, equipment-specific commands for the AS/RS, conveyors, and AGVs. This coordination ensures that a retrieval command becomes a sequence of actions executed by stacker cranes and transport systems. The seamless interaction between WMS and WCS is the core of a functional integrated warehousing solutions architecture.

The Imperative of System Integration and Coordination

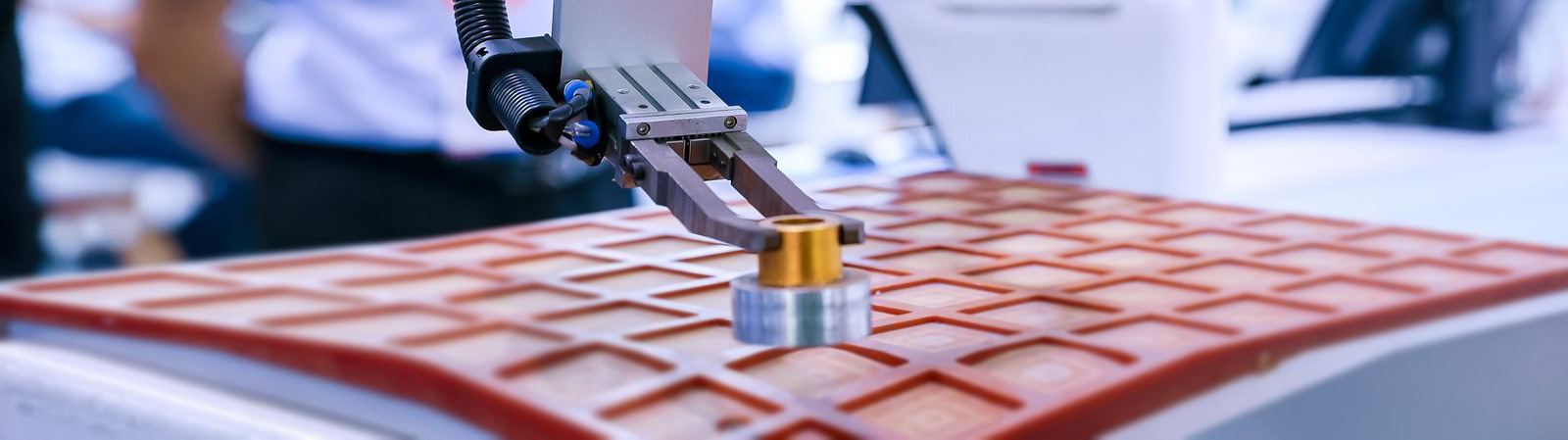

The value of these components is not realized in isolation. The challenge lies in integration—ensuring the WMS software accurately reflects physical stock, that the WCS commands are flawlessly executed by hardware, and that data flows bidirectionally without delay. A disconnect can lead to system gridlock or inventory inaccuracies. Therefore, implementing an integrated warehousing solution involves significant technical collaboration to unify mechanical engineering, control software, and data management. The advantage of working with providers experienced in this ecosystem is their capacity to engineer this cohesion from the outset, designing the material flow for automated grasping, positioning, and transportation within the warehouse framework.

Observing Cohesive Systems in a Technical Forum

Given the complexity of integrating hardware and software, evaluating solutions requires more than reviewing separate product catalogs. Professionals need to see how these systems communicate and operate as a unit. The Intelligent Conveying & Loading/Unloading Solutions section at ITES China presents this exact opportunity. This zone focuses on smart material transfer and showcases the elements of a complete integrated warehousing solution. The exhibition scope allows visitors to examine the physical components—AGVs, stacker cranes, and sorting machines—alongside the operational logic provided by WMS and WCS platforms.

This environment enables practical assessment. Logistics managers can discuss how a specific WMS interfaces with different conveyor systems, or how a WCS manages priority retrieval tasks. They can see the integration of auxiliary equipment, from vibratory feeders for small parts to automated packaging and palletizing lines that complete the outbound process. It provides a consolidated view of how separate technologies combine to create a synchronized flow for raw materials and finished goods. For those planning or upgrading storage infrastructure, this direct access to the technologies and the experts who integrate them at ITES China supports informed planning and vendor selection for these critical operational systems.