How to Choose the Right Machine Tools for Your Production Line

【Introduction】 How to Choose the Right Machine Tools for Your Production Line

How to Choose the Right Machine Tools for Your Production Line

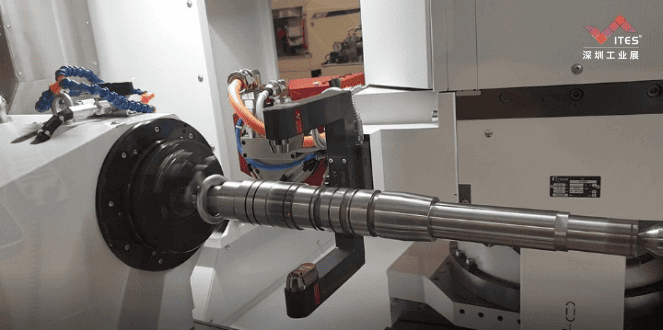

ITES, the company behind the forthcoming Machine Tool Expo 2025, is committed to assisting companies in making well-informed choices on their manufacturing requirements. The correct machine tools may greatly increase productivity, lower expenses, and improve the quality of the final output. However, with so many alternatives available, selecting the right equipment can be a difficult undertaking. We'll walk you through the most important things to think about when choosing machine tools for your production line in this post.

Understand Your Production Needs

Before diving into the world of machine tools, it's crucial to assess your specific production requirements. Consider the types of products you manufacture, the volume of production, and the level of precision needed. At ITES, we encourage businesses to conduct a thorough analysis of their workflow and identify any bottlenecks that could be alleviated by new equipment. The Machine Tool Expo 2025 will provide an excellent opportunity to explore various machine tools tailored for diverse production needs, ensuring you select equipment that aligns with your operational goals.

Evaluate Machine Tool Specifications

Once you have a clear understanding of your production needs, the next step is to evaluate the specifications of potential machine tools. Important factors include accuracy, speed, and versatility. We recommend paying attention to the machine’s compatibility with existing processes and its ability to adapt to future manufacturing trends. During the Machine Tool Expo 2025, attendees will have access to expert consultations that can help clarify technical specifications and enable better decision-making. Understanding these details ensures you invest in tools that enhance productivity while maintaining high standards of quality.

Consider Total Cost of Ownership

When selecting machine tools, it’s essential to think beyond the initial purchase price. The total cost of ownership (TCO) includes maintenance, energy consumption, and potential downtime. At ITES, we advise businesses to factor in these long-term expenses to avoid unexpected financial burdens. Machine tools showcased at the Machine Tool Expo 2025 will come with comprehensive information on TCO, allowing you to make a more informed comparison between different equipment options. A lower upfront cost might seem appealing, but higher maintenance costs or inefficient energy use could lead to bigger savings in the long run.

Conclusion

A crucial choice that affects productivity and profitability is selecting the appropriate machine tools for your production line. You may make well-informed decisions that will help your company by knowing your production requirements, assessing machine tool specs, and taking the total cost of ownership into account. ITES cordially invites you to attend the Machine Tool Expo 2025, where you can learn about the newest advancements in machine tools and locate solutions customized to meet your unique requirements. By working together, we can improve your production capacity and make sure you're ready for the manufacturing industry of the future.