The Influence of Metal Cutting Technologies in Electronics Production

【Introduction】 The Influence of Metal Cutting Technologies in Electronics Production

The Influence of Metal Cutting Technologies in Electronics Production

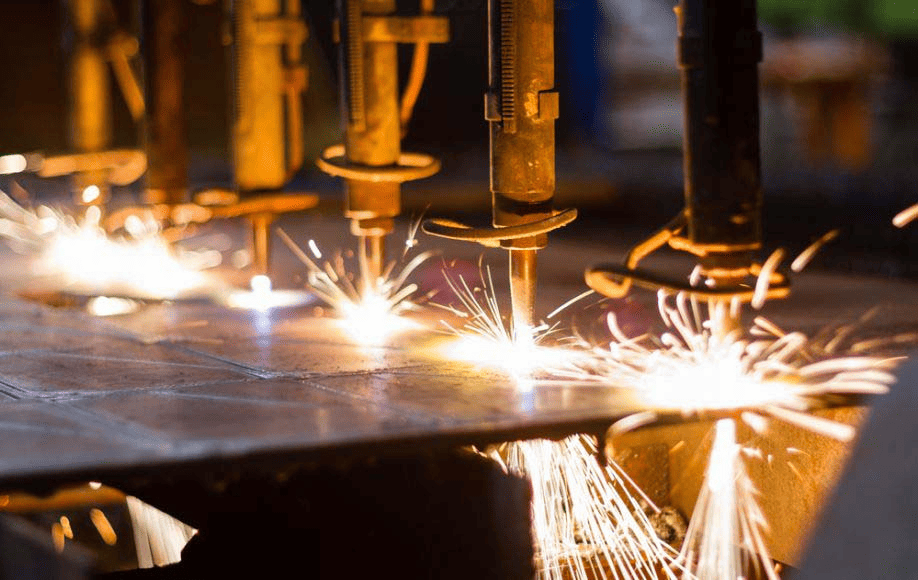

We bring together innovators and leaders in the industry to present the newest technological developments as the organizer of the Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition. The production procedures for electronic components are being revolutionized by metal cutting machine tools, which increase accuracy and efficiency.

Enhancing Precision in Electronic Components

One of the primary benefits of modern metal cutting machine tools is their ability to enhance precision in the production of electronic components. As devices become smaller and more complex, the demand for exact specifications has never been higher. Our exhibitors demonstrate advanced CNC (Computer Numerical Control) machines designed specifically for tight tolerances required in electronics manufacturing. These machines ensure that every cut is accurate, reducing waste and improving overall product quality. The role of precision metal cutting in creating intricate circuit boards and microchips cannot be overstated, and we are proud to showcase innovations that support this essential aspect of production.

Improving Efficiency and Reducing Production Costs

Efficiency is vital in the competitive electronics market, and metal cutting machine tools significantly contribute to streamlining production processes. With rapid advancements in automation and robotics, our featured technologies allow manufacturers to enhance throughput while maintaining high-quality standards. Automated metal cutting systems minimize manual intervention, reducing labor costs and the risk of human error. At ITES, we highlight how these advancements not only boost productivity but also lead to significant cost savings for businesses operating in the electronics sector. By investing in the latest metal cutting machine tools, companies can stay ahead of the curve and respond quickly to market demands.

Addressing Sustainability in Electronics Manufacturing

As industries increasingly turn to sustainable practices, the role of metal cutting machine tools in promoting eco-friendly production methods is gaining attention. At ITES, we advocate for technologies that emphasize waste reduction and energy efficiency. Advanced metal cutting processes are designed to maximize material usage, thereby minimizing off-cuts and scrap materials. Additionally, many modern machines utilize energy-efficient motors and systems that decrease power consumption during operation. By focusing on sustainability, the electronics industry can align with global efforts to reduce carbon footprints, and we are excited to champion these environmentally friendly techniques at our exhibition.

Conclusion

In conclusion, metal cutting machine tools serve as a foundational pillar in the electronics production landscape. Their influence on precision, efficiency, and sustainability cannot be overlooked. At ITES, we are dedicated to promoting the latest innovations and technologies that harness the power of metal cutting machine tools. As the electronics sector continues to evolve, we remain committed to supporting manufacturers in achieving their goals through advanced machining solutions. Join us at ITES to explore how metal cutting technologies are shaping the future of electronics production!