The Knot of Burrs on Curved, Thin-Walled, and Deep-Cavity Die Castings: How Automation Unties It?

【Introduction】 Die Castings、Surface Treatment Technology、Automation Solution Integrator

Introduction: How does surface treatment of automotive die castings rely on polishing and grinding? How does automation reduce costs and boost efficiency? In China’s automotive core component industry chain, the die casting sector is experiencing steady growth.

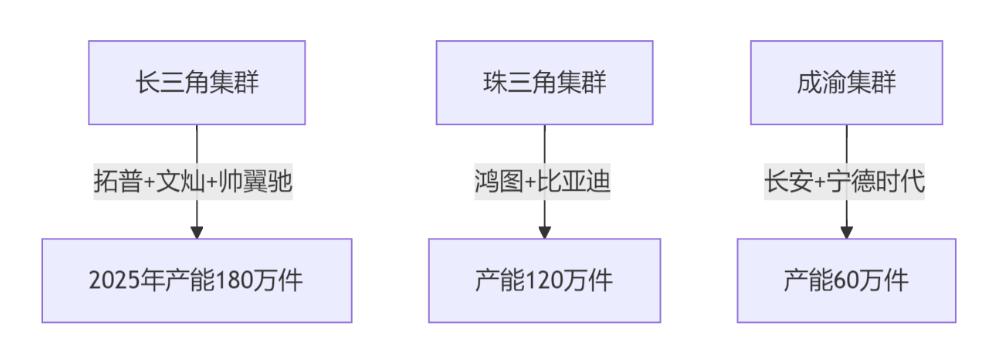

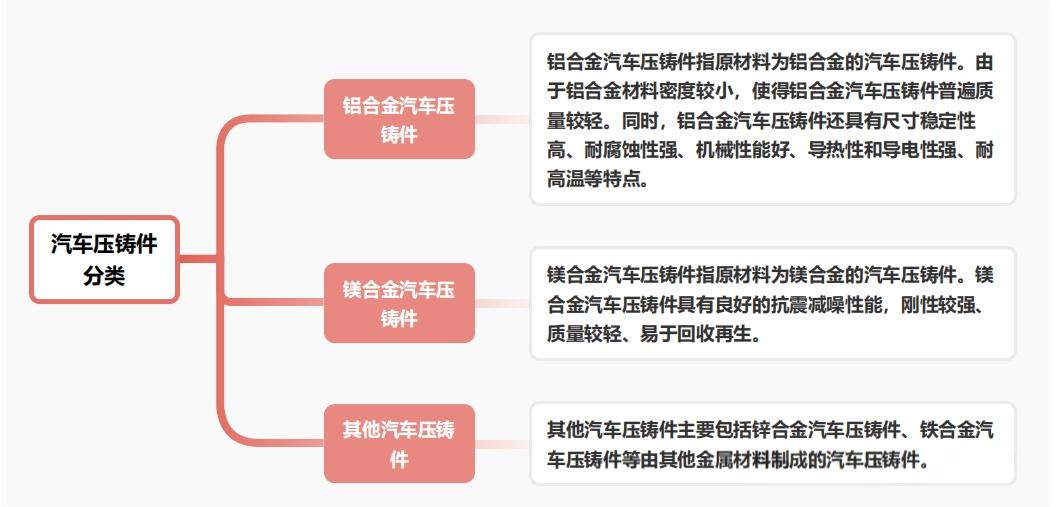

Data shows that from 2017 to 2024, China’s automotive die casting output increased from 484,300 tons to 559,100 tons, with a compound annual growth rate (CAGR) of 2.07%. The market size climbed from 18.988 billion yuan to 26.429 billion yuan, a CAGR of 4.84%. With trends like lightweighting and intelligentization in the new energy vehicle sector, future market share is expected to improve further.

However, in the production of rapidly expanding automotive die castings, polishing and grinding—seemingly a “face-lifting project”—is actually an “inner-strength project” ensuring vehicle safety and quality. Under the trend of integrated die casting, surface treatment will cover a broader scope with stricter quality requirements. So, what exactly do polishing and grinding “grind” for automotive die castings? And why is automation necessary?

Why Must “Surface Work” for Die Castings Be Thorough?

In the manufacturing process of automotive die cast parts, “surface treatment” or “finishing processes” is not only the foundational step for high-end surface treatments like electroplating, spraying, and anodizing but also a dual guarantee of functionality and aesthetic value.

From a safety perspective, burrs and flash formed at parting lines, gates, and other areas after demolding are like “hidden killers” inside the parts. These sharp edges can easily become sources of crack initiation and propagation when the parts bear loads or vibrations. Removing these defects through fine grinding significantly enhances the parts’ fatigue strength and structural reliability.

As the “third space” attribute of automotive interiors strengthens, more die cast parts are used as visible components, such as steering wheel skeletons, center console brackets, and door handle bases. The surface texture of these parts directly affects users’ tactile and visual experiences. Fine polishing delivers a smooth touch and premium metallic luster, increasing product added value.

What Exactly Do Automotive Die Castings “Grind”?

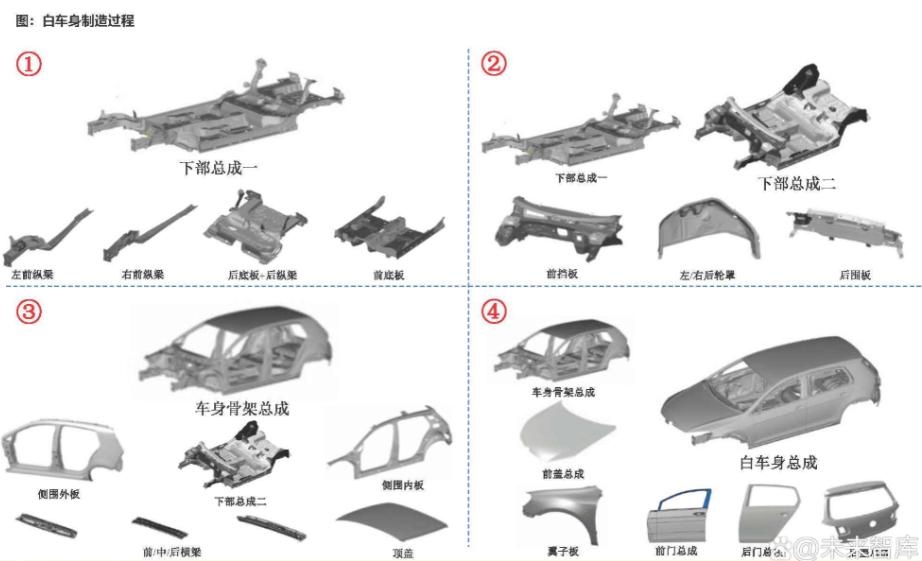

Automotive die cast parts are widely used in powertrain systems, steering systems, and chassis assemblies, covering products like cylinder blocks, cylinder head covers, crankcases, oil pans, generator housings, transmission housings, mounting brackets, and crossbeams. The grinding processes for these die cast components typically focus on the following aspects:

· Grinding of residual parting lines and gates/risers: During die casting, molten metal overflows from mold parting surface gaps to form flash, and residues remain at gates and vents.

· Handling draft angles and internal cavity burrs: Draft angles are designed for easy demolding but tend to accumulate flash; complex internal cavities easily develop burrs at rib intersections.

· Improving surface defects: Imperfections like cold shuts, flow marks, minor scratches, and mold sticking marks require grinding to smooth them out and eliminate visual flaws. Edges also need chamfering to blunt them, prevent cuts, and improve stress distribution.

Take automotive structural parts (e.g., shock towers, longitudinal beams) and interior parts as examples: they often feature complex 3D curved surfaces. Manual grinding struggles to ensure uniform force application across all curves. Aluminum alloy die castings are generally not very hard, but different regions may have varying hardness due to different cooling rates. Thin-walled areas require extremely precise control of grinding pressure and heat to avoid workpiece deformation. Moreover, despite advances in die casting, burrs and flash still occur randomly—their size, position, and shape are not entirely consistent, making errors likely.

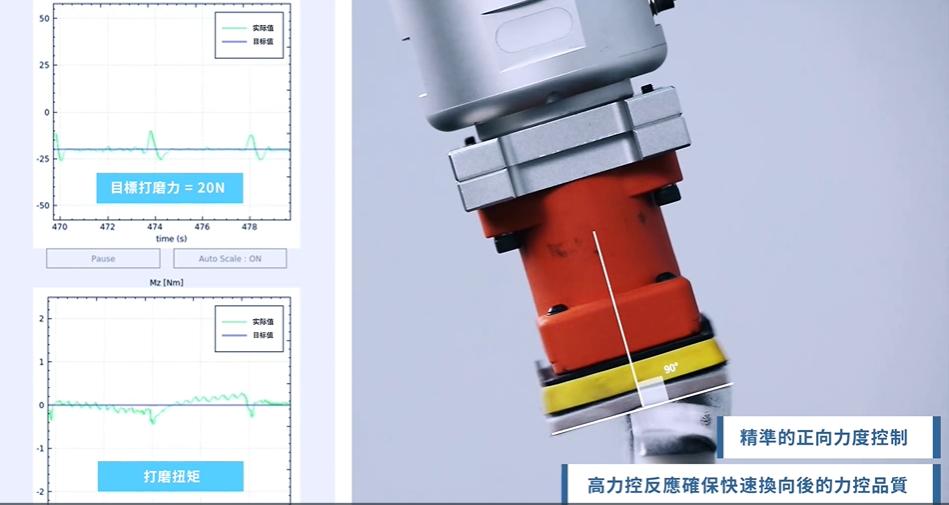

For this reason, automated grinding technology has seen rapid development opportunities. Automated systems use force control technology and precise path planning to ensure each workpiece is ground with the same pressure and trajectory, achieving consistency at the millimeter or even micron level. Robots’ fixed working rhythms far exceed manual efficiency, providing reliable assurance for large-scale production.

Enterprises Have Clever Solutions for Polishing/Grinding Automation

Facing the technical demands of automotive die casting polishing and grinding, equipment providers have rolled out distinctive solutions to enhance processing stability and efficiency.

For complex parting line treatment in die casting, Flexiv Robotics offers 7-axis adaptive robots and polishing/grinding workstations. These can achieve real-time conformability and stable dynamic force control on large-curvature or uneven surfaces, enabling stable high-speed grinding at a linear speed of up to 800 m/s while maintaining a force control accuracy of 0.6N even at high speeds.

STIHL’s grinding robots reduce dust emissions and optimize the production environment through precise force control. Using tools at the end of the grinding unit and optimized motion paths, they maintain constant contact force and ideal grinding angles. Additionally, during weld seam grinding, robots dynamically adjust parameters to avoid surface porosity or slag inclusion, making them suitable for die castings of materials like aluminum and zinc alloys.

For die casting deburring and polishing, Yinglian Technology has launched the robot LP series force-controlled grinding workstations and YLR series force-controlled grinding robots. The YLR series uses a high-rigidity robot structure to avoid errors from deformation or vibration. It also features a self-developed force-position compensator with a maximum contact force of 1,200N, combined with dynamic force control for ±1N accuracy—ensuring constant grinding force to prevent over-grinding or under-grinding.

During aluminum die casting, significant flash and burrs form, but over-cutting must be avoided during deburring. Yuli Instruments’ M5302S interchangeable radial floating grinding head offers ±6° radial float to eliminate discrepancies from inconsistent workpieces. Coupled with controllable constant pressure, it ensures stable cutting amounts and controllable over-cutting.

At next year’s ITES Shenzhen Industrial Exhibition, these companies will showcase their latest polishing/grinding solutions and equipment. Additionally, suppliers covering robotics, tightening, end-effectors, intelligent material handling, and polishing/grinding—including FANUC, Kawasaki, Epson, Huashu, GSK, Hongbai Technology/Zhige Robotics, Outuo Automation, Qilisu, Rongyi, Yuli, Kunwei, Landian, and Lizhun—will present their latest products, creating a panoramic view of precision component production automation. Stay tuned!

ITES Thematic Exhibition—Robotics & Automation Equipment Show’s Precision Component Production Automation Zone: This zone showcases automated solutions and equipment for processes including polishing/grinding, deburring, painting, and cleaning. It provides full-set automated solutions for post-processing of precision parts in industries such as automotive components, 3C electronics, communications, lithium batteries, aerospace, semiconductors, medical devices, furniture, and sanitary hardware. (Click “Read More” at the end for details on more thematic zones~)

If you are also interested in polishing/grinding of automotive components, have innovative processing solutions, and wish to engage with leading automotive enterprises like BYD, GAC Toyota Engine, Daye Motorcycle, and Sanwu Auto to explore cooperation opportunities, welcome to scan the QR code to contact us. Secure your spot at the 2026 ITES Shenzhen Industrial Exhibition and book prime exhibition spaces now!