Five Key Trends to Master the High-End Equipment & Precision Manufacturing Sector

【Introduction】 Precision Machining、Humanoid Robots、Automobiles/Motorcycles (Complete Vehicles)、New Energy Vehicles (Complete Vehicles)

Introduction: What’s trending on the "High-End Equipment & Precision Manufacturing" market search charts this year? To deliver more valuable content, ITES Shenzhen Industrial Fair has launched Expo Insights, a new vertical, professional, and exclusive exhibition research column. In its third installment, we dive deep into the high-end equipment and precision manufacturing sector. Join ITES to explore the changes and opportunities in the industry’s ecosystem so far this year.

Frontline Insights: Hot Trends Driving the Sector

Over the past six months, mature industries like consumer electronics and new energy vehicles have maintained steady growth. Meanwhile, emerging fields—humanoid robots, liquid-cooled servers (driven by AI computing demand), and consumer-grade 3D printing—have seen explosive growth thanks to technological breakthroughs and commercialization, unlocking significant market potential.

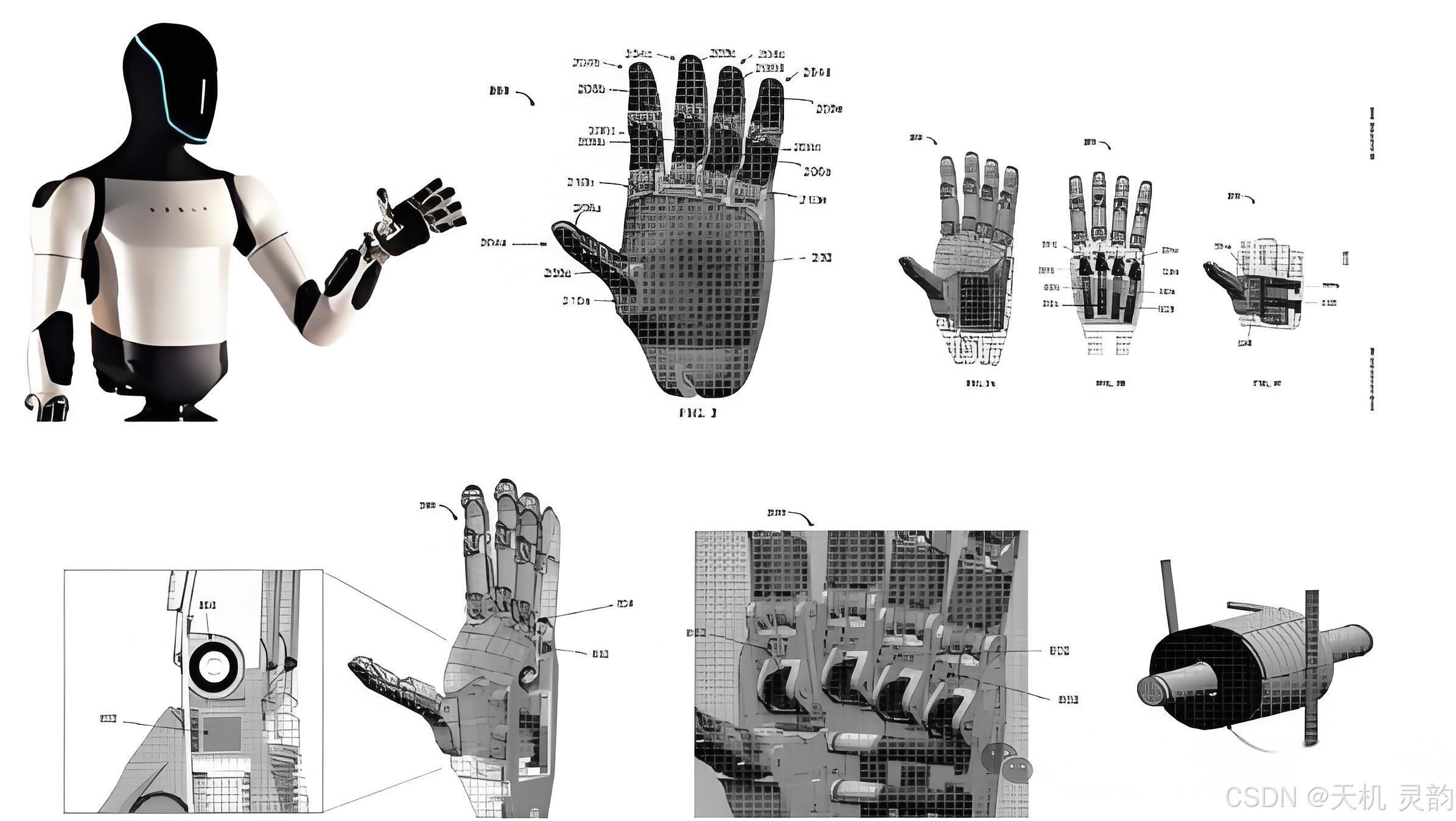

Ø Humanoid Robots

Maket data shows China’s humanoid robot market is projected to reach RMB 8.239 billion by 2025, accounting for ~50% of the global share, leading in industrial concentration globally.

As of September, humanoid robot integrators (e.g., Zhiyuan Robotics, Unitree Robotics, UBTECH, Jizhi Dynamics, and AI No. 2) have announced ToB orders totaling nearly RMB 1 billion. Leading players are accelerating commercial deployment, creating new opportunities for upstream supply chains.

ITES Research Insight

The humanoid robot boom is boosting precision manufacturing growth, with players across the value chain strategically positioning themselves:

1) Core Components: Suppliers like Zhongzhi Machinery, Ringzhen Technology, Dingzhi Technology, and Newstead Technology are ramping up R&D and production of precision reducers, 6-axis force sensors, and robot motors.

2) Precision Parts: Firms such as Donghui Precision, Jinzhijie, and Ruizheng Machinery are strengthening technical capabilities in components like dexterous hand parts and joint shafts. For example, Zhongyi Precision has leveraged ITES to secure motor and shell orders for humanoid robots, entering the smart equipment sector.

Precision Machine Tools: Mass production demand from downstream markets has driven growth in orders for high-end machine tools from manufacturers like Yamazaki Mazak, Tsugami, Aifei MI, and Efort MI.

Ø AI Glasses

According to IDC, global smart glasses shipments reached 2.555 million units in Q2 2025, up 54.9% YoY. China’s Q2 shipments hit 664,000 units, surging 145.5% YoY; full-year shipments are projected to reach 2.846 million units, a 116.4% increase. Brands like Meta, Xiaomi, Ray-Ban Meta, XREAL, Yingmu Tech, and Liweike Tech are driving strong market performance.

ITES Research Insights:

1) Domestic players including Goertek, Luxottica, Lens Technology, Sunny Optical, Yasi Optics, and Shenzhen Voxx are entering the space, spurring order growth.

2) Micro-components like hinges, axles, and temple arms in AI glasses demand ultra-high precision, exceeding the capabilities of traditional machining. This has created opportunities for high-end machine tool suppliers such as Yamazaki Mazak, Yasda, DMG MORI, GF Machining Solutions, and Sodick.

Ø New Energy Vehicle (NEV) Components

China’s NEV component industry revenue hit RMB 1.9 trillion in 2024 and is set for rapid growth in 2025. Core industrial clusters in the Yangtze River Delta (Shanghai, Ningbo) and Pearl River Delta (Shenzhen, Guangzhou) span the full precision manufacturing value chain.

ITES Research Insights:

1) Lightweighting: Driven by extended range requirements, companies like Hongte Precision, Tianrun Industrial, Rongtai Shares, and Yongmaotai are advancing complex magnesium-aluminum alloy part forming and integrated die-casting technologies.

2) Battery Thermal Management: Enterprises such as Aidefu Precision Metal Technology are innovating in battery structural components to meet stringent cooling demands.

Ø Liquid-Cooled Cooling

The AI server market is projected to exceed $400 billion in output by 2025, growing 45% YoY. With Nvidia transitioning from its Hopper to Blackwell series, AI server market share is expected to surpass 70%.

Liquid-cooling adoption is set to rise to 30%, fueling demand for high-value-added components in cooling systems.

ITES Research Insights:

1) Aidefu Precision is expanding into server markets with liquid-cooling heat dissipation trays. Yishan Precision has solved precision fitting challenges at connector ends, excelling in liquid-cooling component R&D and mass production.

Ø Consumer-Grade 3D Printers

Embedded AI algorithms, template recommendations, and adaptive parameter settings have lowered user barriers. Companies like Top3DShop, Creality, and Anycubic are expanding applications, stimulating upstream supply chain activity.

ITES Research Insights:

Components like micro-guides, device frames, lasers, and nozzles in consumer 3D printers demand higher precision. Firms including Jinzhijie, Shengdingyuan, and Yishan Precision are supplying high-standard precision structural parts.

Supply Chain Developments

Upstream and downstream players are expanding to capture incremental markets:

1) Sodick: Achieved breakthroughs in connector precision injection molding, offering fiber optic connector molding and wire-cutting solutions with 0.3μm ultra-precision machining. It will debut new products at ITES Shenzhen Industrial Fair next March.

2) Power Machinery:Will launch a China-premiere ultra-precision turn-mill composite machine (μm-level precision) at next year’s ITES. Pre-booked by clients in East and South China, it targets high-precision machining of small liquid-cooling components.

3) Liebherr:Its Chongqing Yongchuan plant—China’s sole CNC machine tool production base—has officially opened, with an annual capacity of 80 high-end CNC machines and automated lines, generating over RMB 600 million in output. Initial products include LGG280 high-precision gear machining centers.

4) DN Solutions:Acquired Heidenhain for KRW 67.8 billion (~$48.5 million), absorbing its machining center expertise in automotive, aerospace, and defense to enhance competitiveness.

5) GF Machining Solutions:Completed the acquisition of United Grinding, expanding its portfolio to 15 brands. The new group, UNITED Machining Solutions, now generates over $1.5 billion in sales, becoming the world’s largest machine tool manufacturer.

6) Chenxing Intelligent:Accelerating construction of its high-precision large-component project in Dongguan (61,390㎡), focusing on R&D and production of universal parts, high-end custom components, carbon fiber molds, jigs, and fixtures.

7) Everwin Precision: With over a decade in robotics, it has supplied parts to global humanoid robot brands, shipping over 800,000 components. From January to August this year, its humanoid robot component business generated over RMB 80 million in revenue.

8) Luxshare Precision:Investing RMB 5 billion in a robot headquarters in Changshu, Jiangsu (completion by year-end). Upon operation, it will achieve RMB 10 billion in annual output, focusing on industrial automation, robots, and core component R&D, manufacturing, and sales.

Technology Radar

Enterprises are rolling out innovations to drive industry advancement:

1) Röders:Launching the new RPT series with PRECITEMP® constant temperature technology, maintaining ≤1μm precision even with temperature fluctuations. Offers I, II, and III-level thermal control options for flexible precision tuning.

2) Toshiba Machine:The LA-350 series rigid heavy-duty lathe features a robust bed, flexible workspace, powerful cutting, and precise power units, ideal for large, complex workpieces.

3) Brother Machines:The U500Xd2 machining center for humanoid robot joints includes a 5-axis rotary table and multi-tool setup (up to 28 tools), addressing challenges in complex aluminum joint machining, chip removal, and efficiency.

4) Fraunhofer:Unveiled the smartTOOL smart tool holder with high-frequency sensors (10kHz sampling rate) to monitor cutting forces and vibrations, enhancing precision in finishing, heavy cutting, and more.

5) L.K. Group:Expanding in magnesium alloy die-casting and Thixomolding® to address lightweighting, heat dissipation, precision, and cost in robotics, leveraging material-process synergy.

6) Marposs:Launched the 3rd-gen mold surface temperature monitoring system (TTV) with ±2°C accuracy (vs. ±5°C previously), boosting OEE in modern die-casting and Giga casting machines.

7) ScanWorks:Released the KSCAN-E wireless 3D scanner with 0.020mm precision, supporting aerospace, construction machinery, energy, and automotive measurement across small and large scenes.

Event Calendar

ITES drives market insights and connects supply-demand through targeted activities:

1) Brother SPEEDIO DAY Open House (July)

Co-hosted by ITES, this event gathered 50+ procurement and technical leaders from Foxconn, Everwin Precision, AVIC Optoelectronics, and Midea Precision Molds to explore 5-axis machining for flexible precision manufacturing.

2) Industry Chain Exploration: Sindex Mold (August)

ITES, in partnership with Gongchuanglian and TMTpost, organized a visit to Sindex Mold’s 70,000㎡ facility, showcasing high-precision, fast-turnaround mold manufacturing. Over 40 representatives from Bandai, Hasbro, Mattel, and other firms participated.

3) Industry Chain Exploration: Guangzhou MINO Automation (September)

ITES, with Gongchuanglian and TMTpost, hosted the third event at MINO Automation. Attended by 100+ delegates from BYD, Dongfeng Nissan, and experts, it focused on “AI-Driven Quality Inspection for Automotive Parts,” addressing AI’s role in overcoming detection challenges.