How Does a Rotary Table Work

【Introduction】 How Does a Rotary Table Work

A fundamental question in precision manufacturing involves the method for accurately rotating a workpiece to present multiple sides to a cutting tool. The answer often involves a specialized piece of equipment known as a rotary table. This device provides controlled, precise angular positioning, which is essential for complex machining operations like milling curved slots, drilling holes on a precise bolt circle, or creating intricate geometric features. For professionals evaluating automated machining solutions, understanding the operational principle of this component is a step toward optimizing multi-axis workflows. We at ITES China see rotary tables as critical enablers of advanced manufacturing, a category prominently featured by numerous rotary table manufacturer exhibitors at our event.

The Mechanical Principle Behind Precise Angular Movement

At its core, a rotary table functions by converting controlled input into highly accurate rotational output. The most common design utilizes a worm gear drive system. A precision-ground worm screw is turned by a motor, which engages with a worm wheel fixed to the table's central spindle. This arrangement provides a high reduction ratio, meaning many turns of the input worm are required to produce a single revolution of the output table. This gearing effect is what allows for fine angular adjustments and exceptional positioning resolution, often down to arc-seconds. The system is housed within a rigid body that ensures stability under load, and the rotation is typically controlled by a CNC system that integrates the table's movement with other machine axes for synchronized operations. This principle allows a rotary table manufacturer to produce units that serve as a reliable fourth or fifth axis for machining centers.

The Advantage of Sourcing from Specialized Production Hubs

The reliability and accuracy of a rotary table depend heavily on the quality of its core components—the gears, bearings, and sealing systems. Sourcing from established manufacturing regions offers distinct advantages. A concentrated industrial ecosystem allows rotary table manufacturers to access specialized supply chains for high-precision mechanical parts and advanced drive motors. This environment fosters technical refinement, leading to products that balance dynamic load capacity with positioning accuracy. Furthermore, the competitive landscape encourages innovation in areas like direct-drive technology, which eliminates mechanical backlash for even higher precision. For a global buyer, engaging with this ecosystem means accessing a spectrum of solutions, from robust manual indexing tables to fully integrated, CNC-ready models, all designed for rigorous industrial use.

Evaluating Capabilities and Innovations at an Industry Gathering

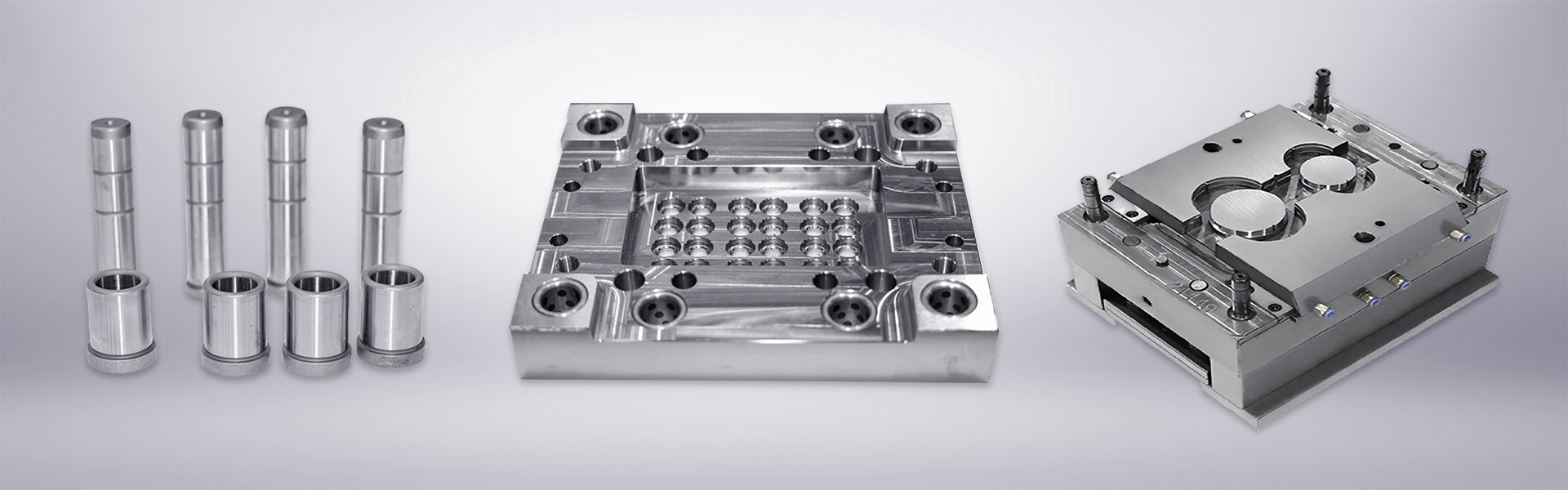

Technical specifications provide a foundation, but selecting the right rotary table requires a hands-on assessment of build quality, control integration, and application support. This practical evaluation is best conducted where multiple rotary table manufacturers gather to demonstrate their latest technologies. The upcoming session at ITES China provides this exact environment. The exhibition floor will feature a range of exhibits, from standard horizontal rotary tables to tilting models that enable complex multi-face machining in a single setup. Visitors can examine the internal construction of displays, discuss load and speed parameters with engineers, and see how different models from various rotary table manufacturers interface with CNC controls. This direct comparison is invaluable for machining professionals who need to specify equipment for demanding applications in mold making, aerospace component fabrication, or precision automotive part production.

The operational principle of the rotary table—transforming precise input into controlled rotation—is a cornerstone of modern multi-axis machining. Its effective implementation relies on precision manufacturing and integrated design, strengths found within specialized industrial clusters. While technical documents outline capabilities, the process of specification and procurement benefits from direct engagement with technology and its creators. The assembly of numerous rotary table manufacturers and their latest exhibits at ITES China creates a focused forum for this necessary dialogue. We facilitate this convergence, offering a platform where the theoretical mechanics of angular positioning meet the practical demands of the factory floor, supporting the industry's continuous advancement in manufacturing complexity and precision.