Optimizing CNC Machining Performance with Tool Magazine Management

【Introduction】 Optimizing CNC Machining Performance with Tool Magazine Management

Effective management of machine tool peripherals is a recognized factor in achieving sustained manufacturing productivity. Among these, the tool magazine represents a critical subsystem whose operation directly influences machine uptime and job flexibility. At ITES China, our analysis of machining cell efficiency consistently highlights the impact of reliable tool logistics. A well-configured CNC tool magazine does more than store cutters; it serves as the operational foundation for uninterrupted, multi-process machining. Its strategic management is a practical component of lean manufacturing principles applied to precision engineering.

The Direct Impact of Tool Magazine Strategy on Machining Efficiency

The primary function of a CNC tool magazine is to provide rapid, automatic tool changes, thereby minimizing non-cutting time. However, its role extends deeper into production planning. Effective management involves the logical organization of tools within the magazine, aligning their placement with specific job sequences to reduce search and retrieval time. It also encompasses capacity planning—ensuring the magazine holds the necessary tools for scheduled jobs without excessive, idle inventory that consumes physical space and management attention. Furthermore, a robust system for tool life monitoring and pre-setter integration ensures that fresh, correctly measured tools are delivered to the spindle without manual intervention. This orchestration of physical storage, data management, and predictive maintenance turns the tool magazine from a passive holder into an active contributor to overall equipment effectiveness (OEE). For our partners, optimizing this subsystem is a direct method to enhance throughput.

Integration with Core Components for System-Wide Precision

The performance of a CNC tool magazine cannot be isolated from the rest of the machining center's core components. Its operation is intrinsically linked to the spindle's interface, the accuracy of the rotary table's positioning, and the rigidity provided by linear guides and ball screws. A rapid tool change is only valuable if the spindle nose and tool holder maintain perfect taper contact for repeatable accuracy. The dynamic performance of the machine's axes, driven by precision screws and guides, must compensate for the changing mass and balance as tools of different weights and lengths are exchanged. Therefore, evaluating a CNC tool magazine requires a systems perspective. It is one vital node within a network of interdependent components—spindles, rotary tables, drives, and controls—that together define a machine's capability to perform complex tasks for industries like automotive or medical devices with required precision.

A Focused Venue for Component Evaluation and System Integration

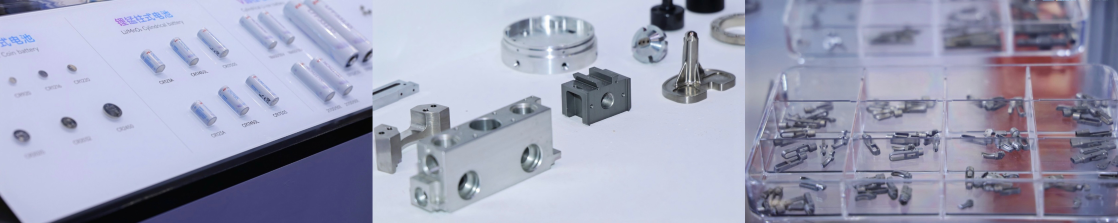

To make informed decisions on such integrated systems, industry professionals require access to concentrated technical displays. The Core Functional Components zone at a major manufacturing exhibition provides this necessary environment. This zone moves beyond showcasing finished machines to focus on the subsystems that define their performance. Here, visitors can examine a wide array of tool magazine designs—from carousel-style to chain-type magazines—alongside the high-precision spindles, rotary tables, and linear motion systems they must work with. This concentrated setting allows for direct comparison of technical specifications, build quality, and compatibility.For an event like ITES China, this interactive environment proves invaluable. The exhibition enables engineers and sourcing teams to assess firsthand how a specific CNC tool magazine from one supplier interfaces with a spindle from another. This direct comparison facilitates a deeper understanding of real-world integration and uncovers potential performance synergies, ultimately empowering attendees to make more informed procurement and specification decisions.

This practical approach to tool magazine management underscores its role as a key lever for machining efficiency. Moving from understanding its standalone function to appreciating its integration within a system of precision components reveals the depth of planning required for optimal performance. The specialized exhibition zone dedicated to these core functional components offers a unique opportunity for this holistic evaluation. It allows manufacturing engineers and procurement specialists to engage directly with the technologies that form the backbone of modern CNC equipment. For entities focused on operational excellence, such as ITES China, engaging with this focused segment of the supply chain is a strategic step toward building more reliable, efficient, and capable manufacturing processes, directly linking component selection to production outcomes.