Laser Welding vs. Arc Welding: Which Technology Suits Your Production Needs?

【Introduction】 Laser Welding vs. Arc Welding: Which Technology Suits Your Production Needs?

Manufacturing professionals often face a critical technical choice between laser welding and arc welding for their assembly lines. Each process delivers robust metal joints but follows a different physical approach, with direct consequences for speed, quality, and application scope. We at ITES Shenzhen understand that this selection influences production efficiency, component integrity, and total operational cost. This analysis describes the core attributes of both methods, considers the context of sourcing from Chinese suppliers, and highlights a direct method for evaluating these technologies within an industrial setting.

Fundamental Principles and Operational Considerations

The operational distinction between these technologies is foundational. Laser welding uses a concentrated beam of light energy to create a deep, narrow weld seam with exceptional speed and localized heat input. This minimizes thermal distortion, making it applicable for thin materials, intricate geometries, and hermetic seals often required in electronics or precision mechanics. Arc welding generates heat via an electric arc, melting both the workpiece and a consumable electrode to form the weld pool. Processes like MIG/MAG offer high deposition rates for thicker sections, while TIG welding provides precise control for high-integrity joints on metals like aluminum or stainless steel. The decision matrix involves material thickness, joint design, desired production throughput, and the acceptable level of post-weld finishing.

Capabilities within the Chinese Manufacturing Landscape

The global industrial ecosystem is supported by a mature and diversified network of equipment producers. For organizations evaluating laser welding equipment manufacturers, the Chinese market presents options ranging from high-power multi-kilowatt systems for automotive battery trays to finely tuned pulsed lasers for medical device fabrication. Concurrently, firms looking at arc welding machine manufacturers can source from a vast array of products, including inverter-based machines for manual shop-floor use, automated submerged arc systems for heavy plate, and sophisticated robotic welding packages. This concentration of manufacturers fosters competition, innovation in power source design and control software, and the development of a parallel supply chain for consumables, torches, and peripheral automation components.

A Focused Venue for Practical Assessment at ITES Shenzhen

Technical data sheets provide necessary specifications, but practical assessment remains vital for procurement decisions. The Welding Technologies & Equipment zone at ITES Shenzhen is designed to facilitate this hands-on evaluation. This dedicated segment transforms theoretical comparisons into observable demonstrations and expert consultations. The zone's composition allows for a thorough investigation of current capabilities. A primary exhibition highlight is the integration of welding processes into automated and intelligent work cells. Attendees can examine systems where welding power sources are seamlessly coupled with robotics, vision-based seam tracking, and adaptive process control, emphasizing repeatability and reduced manual intervention.

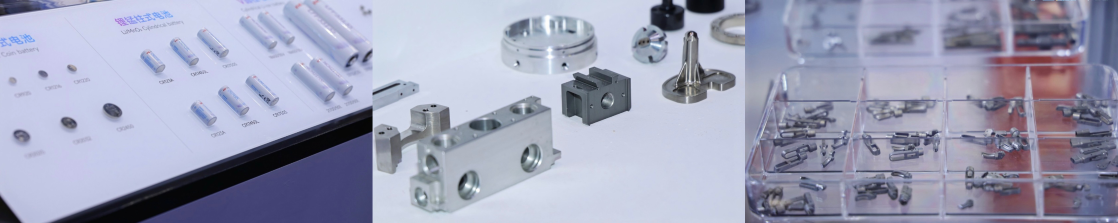

The group of exhibitors forms a concentrated cross-section of the industry's supply base. ITES Shenzhen brings together these high-quality enterprises, including prominent laser welding equipment manufacturers and specialized arc welding machine manufacturers. This assembly permits direct comparison of machine performance, build quality, user interface design, and after-sales support structures. Furthermore, the presence of companies offering welding auxiliary equipment, specialized tools, and safety solutions allows visitors to plan complete workstation integration. The exhibited technologies are demonstrated in context, showing their application in serving the precision component processing needs of sectors such as automotive and motorcycle manufacturing, new energy power systems, consumer electronics, home appliances, and structural fabrication for shipbuilding and construction.

Identifying the correct welding technology requires a balanced review of technical requirements, operational constraints, and financial parameters. The extensive capabilities of laser welding equipment manufacturers and arc welding machine manufacturers within the Chinese industrial base provide a substantial range of reliable options. For professionals tasked with specifying or procuring welding systems, the curated environment of the Welding Technologies & Equipment zone at ITES Shenzhen offers a direct path to validation. We provide this platform to bridge the gap between process selection and confident investment, connecting specific manufacturing challenges with functional solutions and credible suppliers.