An Overview of Tube Bending, Stretching, and Cold Forming Processes

【Introduction】 An Overview of Tube Bending, Stretching, and Cold Forming Processes

From structural frameworks in automotive design to the intricate components in medical devices, the shaping of metal tubing is a foundational manufacturing activity. For professionals sourcing components or machinery, a clear grasp of the core techniques—tube bending, stretching, and cold forming tube processes—is essential. This knowledge informs material selection, design feasibility, and supplier evaluation. At ITES China, we observe these processes as the cornerstone of advanced metalworking, reflecting the technical depth present within the China tube bending and forming sector. This article examines these methods and their industrial applications, before focusing on a primary venue for engaging with the innovation driving this field.

.png)

The Science Behind Three Core Tube Forming Methods

Tube forming is not a singular operation but a family of processes, each governed by specific mechanical principles. Tube bending, the most recognized, involves the plastic deformation of a tube around a die or mandrel. The key challenge is maintaining the cross-sectional integrity of the tube, preventing wrinkles on the inner radius or excessive thinning on the outer radius. Stretching, often involving stretch forming, uses tensile force to elongate and shape a tube over a form, which is valuable for creating large, gentle contours. The cold forming tube process is a broader category where metal is shaped at or near room temperature. This includes techniques like swaging, flattening, and roll forming, which alter the tube's diameter or profile through high pressure. Cold forming tube methods generally enhance the strength and surface finish of the final product due to work hardening, a significant advantage for high-performance applications.

The Role of Chinese Suppliers in the Global Tube Fabrication Chain

The global supply chain for fabricated tubing relies heavily on specialized manufacturers, and the China tube bending and forming segment has developed considerable capacity. This development is not merely based on scale but on an integrated supply ecosystem. Access to raw materials, a concentration of precision machinery producers, and a deepening pool of process engineering expertise have positioned these suppliers as critical partners. For industries from new energy vehicles to aerospace, partnering with a proficient China tube bending specialist can streamline prototyping and production. These suppliers often bring experience in optimizing forming parameters for different alloys, which directly impacts component cost, durability, and weight. The supply chain advantage lies in this combination of technical capability, vertical integration, and responsive manufacturing philosophy.

Engaging with Innovation at ITES China’s Dedicated Zone

To witness the practical application and evolution of these technologies, industry professionals attend specialized exhibitions. ITES China features a focused zone on tube processing and automated solutions. This zone provides a direct channel to the latest advancements, moving beyond theory to tangible equipment and finished components. We offer a detailed look at what this gathering presents. The exhibition highlights center on complete manufacturing solutions. Visitors encounter a comprehensive range of new products, from advanced CNC tube benders and servo-electric stretching machines to automated cold forming tube systems. The focus extends beyond primary forming to include essential secondary operations such as precision welding, chamfering, polishing, and finishing, which are crucial for final part qualification.

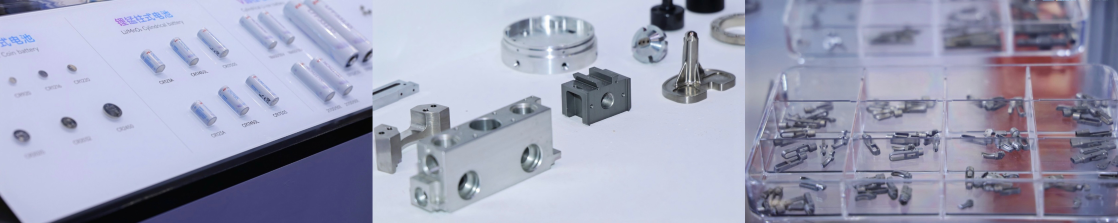

The exhibitors comprise both leading machinery manufacturers and highly skilled contract fabricators. This dual presence allows visitors to compare equipment for in-house production with the option of outsourced precision parts. The exhibits themselves serve as functional case studies, demonstrating how these processes manufacture components for critical industries. Attendees can see firsthand how specific techniques are applied to create parts for new energy vehicle battery frames, medical device supports, architectural hardware, and components for aerospace and shipbuilding. This direct engagement with technology and suppliers is invaluable for making informed procurement and partnership decisions.

Gaining a functional knowledge of tube bending, stretching, and cold forming tube processes provides a firm basis for industrial sourcing and design. The technical maturity within the China tube bending community, supported by a robust supply chain, presents a reliable resource for global manufacturing. For those seeking to specify equipment or source precision tubular components, ITES China’s dedicated zone serves as a concentrated hub of relevant technology and expertise. We at ITES China facilitate these connections, providing a platform where engineering challenges meet practical, advanced manufacturing solutions.