How Turnkey Post-Processing Automation Lines Reduce Labor Cost and Improve Yield

【Introduction】 How Turnkey Post-Processing Automation Lines Reduce Labor Cost and Improve Yield

As manufacturing moves toward higher mix and tighter tolerances, post-processing has become a decisive factor for cost and quality. Manual deburring, cleaning, inspection, and part transfer often account for a large share of labor input and variability. At ITES China, we see many suppliers addressing this gap by adopting precision machining automation as part of an integrated workflow. When post-processing is designed as a turnkey automation line rather than a collection of isolated stations, labor dependency is reduced, process windows become clearer, and yield improves through repeatable control. This shift is particularly relevant for China’s manufacturing ecosystem, where suppliers balance scale, flexibility, and delivery stability for global customers.

Why Turnkey Post-Processing Automation Changes Cost Structures

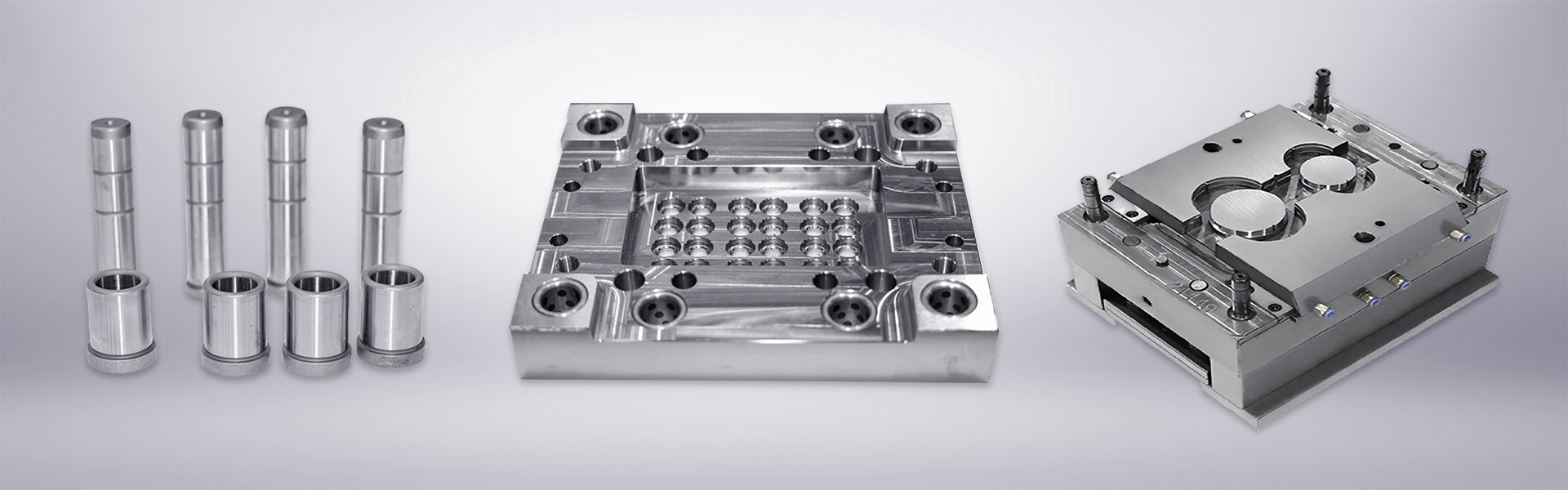

A turnkey post-processing automation line connects machining output directly to standardized finishing, cleaning, measurement, and packaging steps. Instead of relying on skilled operators to move parts and judge quality, robots and automated fixtures execute predefined actions with consistent timing and force. From our perspective, this approach reduces indirect labor linked to supervision, rework coordination, and shift balancing. More importantly, yield improves because process deviations are detected earlier through inline inspection and data feedback. In practice, suppliers using machining automation ITES Shenzhen solutions often report smoother takt times and fewer bottlenecks between CNC machining and final acceptance. The result is not only lower labor cost per unit, but also a more predictable output that supports long-term contracts and stable pricing.

Supply Chain Advantages from Chinese Automation Integration

China’s supplier base has developed strong capabilities in system integration, fixtures, and application engineering, making turnkey automation more accessible across different production volumes. By combining local component sourcing with mature integration experience, suppliers can tailor post-processing automation to part geometry, material, and batch size without excessive customization risk. At ITES China, we observe that automation projects increasingly start from the post-processing stage, where variability is highest and returns are more immediate. This trend strengthens supply chain resilience: standardized automated steps reduce dependency on individual skills and help suppliers maintain yield even during workforce fluctuations. Over time, data collected from automated lines feeds continuous improvement, aligning cost control with quality assurance rather than short-term labor savings.

Exhibition Insights and Industry Exchange at ITES Shenzhen

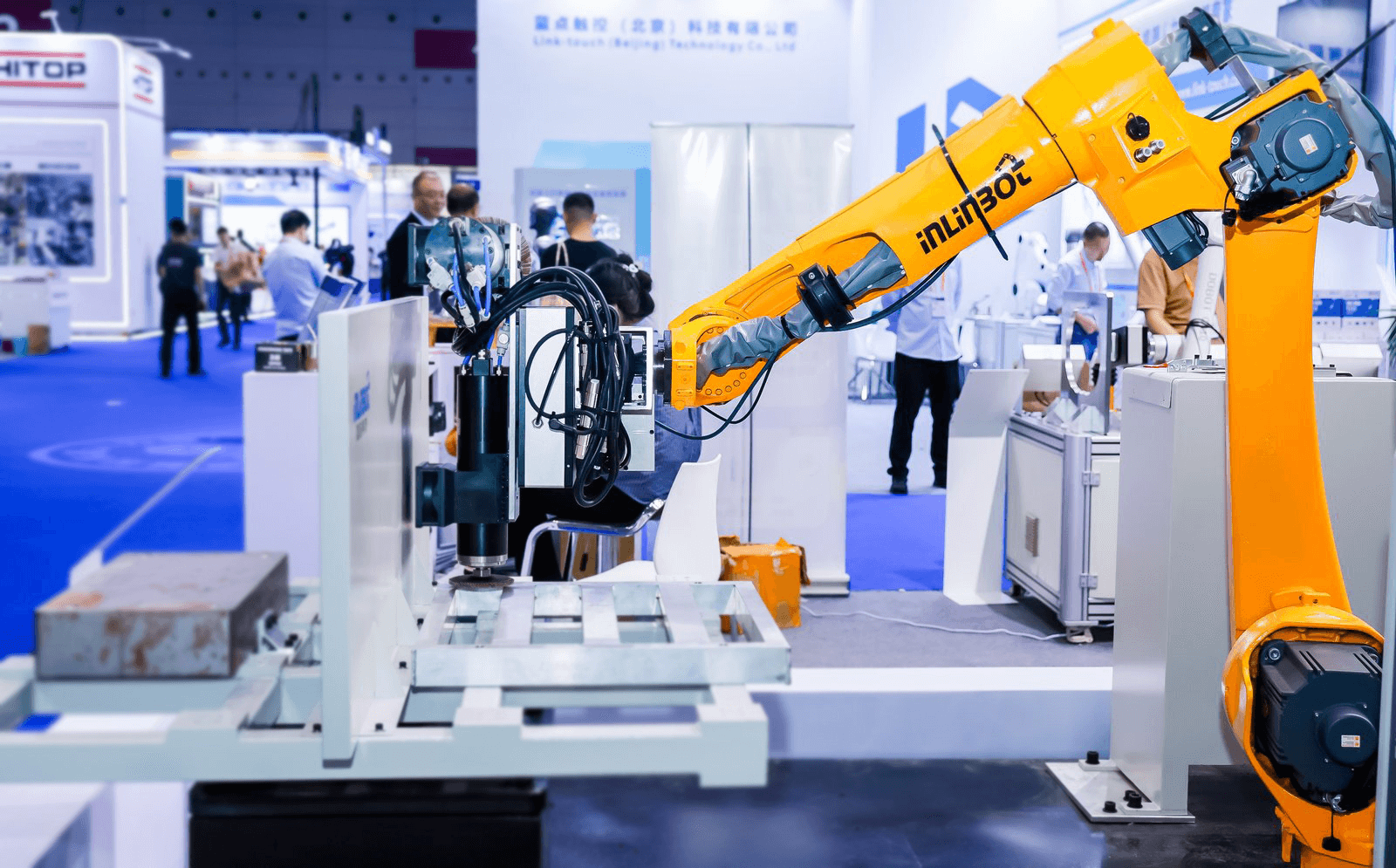

These practical developments are reflected on the show floor at ITES China, where turnkey post-processing solutions are presented as complete production concepts rather than single machines. At the machining automation ITES Shenzhen exhibition, visitors can see automated deburring cells, washing and drying systems, inline measurement, and robotic handling integrated with CNC machining. We also highlight flexible post-processing lines that support different part families, demonstrating how automation can scale with changing orders. Through forums and live demonstrations, the exhibition connects equipment builders, integrators, and end users, offering a clear view of how post-processing automation fits into real production environments.

Conclusion: Turning Automation into Measurable Manufacturing Value

The move toward turnkey post-processing automation is less about replacing people and more about stabilizing outcomes. By embedding precision machining automation into finishing and inspection stages, manufacturers reduce labor exposure while improving yield consistency. From a supply chain perspective, this approach supports reliable delivery and transparent quality control. At ITES China, we position the machining automation ITES Shenzhen platform as a place to evaluate these solutions in context, compare system approaches, and understand how automation decisions translate into long-term operational value rather than short-term gains.