Top Robotic Grinding & Polishing Solutions for Automotive, 3C, and Aerospace Components

【Introduction】 Top Robotic Grinding & Polishing Solutions for Automotive, 3C, and Aerospace Components

As global manufacturing continues to evolve, robotic grinding and polishing have become essential processes for producing complex components with stable surface quality. Across automotive, 3C electronics, and aerospace manufacturing, suppliers are increasingly adopting precision machining automation to meet tighter tolerances, shorter lead times, and more diversified production requirements. In China’s advanced manufacturing ecosystem, we observe growing demand for flexible robotic machining systems that can handle different materials and geometries while maintaining process consistency. Within this context, platforms such as ITES China play an important role in connecting equipment suppliers, system integrators, and end users across the industrial value chain.

Why Robotic Grinding and Polishing Matter in Modern Manufacturing

Robotic grinding and polishing address long-standing challenges in manual finishing, including operator variability, labor intensity, and inconsistent surface results. In automotive applications, these systems are widely used for engine components, structural parts, and aluminum housings, where dimensional stability and surface integrity directly affect downstream assembly. For 3C products, compact geometries and high cosmetic requirements make automated finishing a practical solution for frames, shells, and precision parts. Aerospace manufacturing further raises the bar, as robotic systems must process high-strength alloys while complying with strict quality and traceability standards. By integrating sensors, force control, and adaptive paths, robotic machining enables suppliers to balance efficiency with controlled material removal, supporting both batch production and customized orders.

China’s Supply Chain Advantages and System Integration Capabilities

China’s manufacturing supply chain offers a mature environment for deploying robotic grinding and polishing solutions at scale. Equipment manufacturers, robot brands, abrasive suppliers, and automation integrators operate within close proximity, enabling faster system optimization and application testing. For international buyers, this ecosystem supports cost-efficient sourcing without compromising process reliability. Many solution providers now combine offline programming, simulation software, and data monitoring to support continuous improvement. Events like ITES Shenzhen highlight how local system integrators adapt robotic machining cells for automotive platforms, consumer electronics lines, and aerospace component workshops, demonstrating practical applications rather than conceptual showcases.

From Technology Showcase to Practical Solutions at ITES

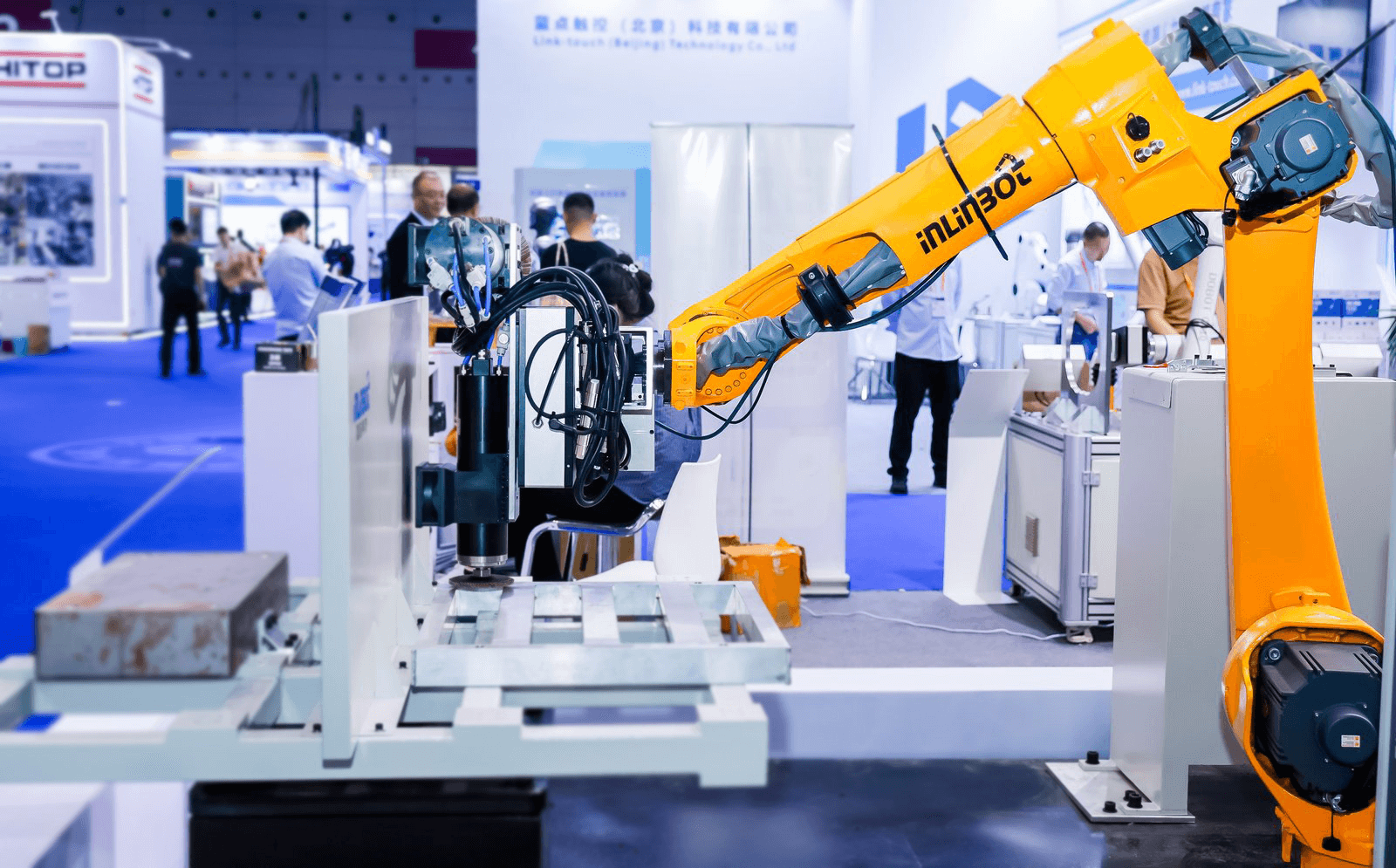

As an industry-facing platform, ITES China focuses on presenting applied manufacturing technologies that align with real production needs. At the exhibition, robotic grinding and polishing systems are typically demonstrated alongside CNC equipment, automation units, and digital manufacturing solutions. Exhibitors cover a wide range of applications, from deburring and surface finishing to hybrid setups combining milling and polishing within a single cell. Visitors can explore complete solutions, including robots, end-effectors, abrasive tools, and control software, helping manufacturers evaluate how precision machining automation can be integrated into existing lines. These displays also reflect how robotic machining supports multi-industry requirements through modular design and scalable configurations.

Conclusion: Exploring Robotic Finishing Solutions Through Industry Collaboration

Rather than positioning robotic grinding and polishing as a single-piece solution, we see it as part of a broader manufacturing system that combines equipment, process knowledge, and supply chain coordination. By engaging with platforms such as ITES Shenzhen, manufacturers gain direct exposure to solution providers who understand automotive, 3C, and aerospace requirements in practical terms. Through live demonstrations, technical exchanges, and supplier networking, the exhibition helps bridge the gap between concept and implementation. For companies evaluating robotic finishing technologies, participating in ITES China offers a structured opportunity to assess solutions, compare approaches, and identify partners aligned with long-term production goals.