Top Industrial Applications of Modern Drilling Machines

【Introduction】 Top Industrial Applications of Modern Drilling Machines

Modern industrial processes demand efficiency, precision, and adaptability. At ITES China, we focus on showcasing advanced drilling technologies that meet these requirements. Our exhibits highlight the latest drilling machine manufacturers' innovations, featuring machines capable of high-precision operations across diverse industrial sectors. From automotive components to medical devices, the scope of modern China drilling machine applications continues to expand. By integrating intelligent control systems and automated monitoring, these machines not only enhance operational efficiency but also reduce human error, making them essential for modern manufacturing environments.

Common Applications

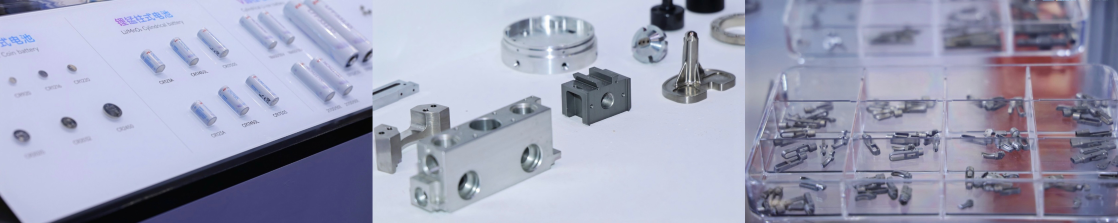

Industrial drilling machines play a crucial role in manufacturing complex components. At ITES China, our exhibits include vertical drilling machines, deep hole drilling machines, and bench drilling machines designed for applications in automotive, aerospace, 3C electronics, and medical equipment production. These machines are essential for precise shaft processing, crankshaft machining, and other tasks where dimensional accuracy and surface finish are critical. For example, deep hole drilling machines are widely used in aerospace for engine component manufacturing, while bench drilling machines support smaller, high-precision parts in medical devices. Additionally, these machines are increasingly applied in energy equipment and industrial machinery, showcasing their versatility in handling materials ranging from aluminum to hardened steel.

How Modern Drilling Machines Improve Productivity

Our China drilling machine solutions are engineered to enhance productivity while maintaining high-quality standards. Multi-axis drilling centers allow simultaneous operations, reducing cycle times and improving repeatability. Integrated CNC systems enable precise control over feed rates and spindle speeds, minimizing errors and material waste. By adopting such advanced machines, our customers experience significant efficiency gains in both prototype and mass production environments. At ITES China, we emphasize the practical benefits of these technologies, demonstrating how modern drilling machines combine automation, accuracy, and reliability for industrial workflows. Operators also benefit from intuitive user interfaces and safety features, which improve training efficiency and overall shop-floor safety.

Where to Find Reliable Drilling Machine Manufacturers

Finding dependable drilling machine manufacturers is essential for sustained industrial performance. In China, numerous manufacturers offer a wide range of drilling solutions, from standard bench models to specialized deep-hole machines. At ITES China, we provide a platform where buyers can explore verified suppliers and assess machines firsthand. Attending our exhibition allows professionals to evaluate equipment, understand technical specifications, and engage directly with manufacturers. This connection ensures that businesses can select the most suitable China drilling machine solutions for their specific industrial needs while gaining insights into the latest advancements in drilling technology. Furthermore, visiting ITES China enables decision-makers to compare multiple suppliers efficiently, ensuring informed purchasing decisions without the risk of compromise.

Conclusion: Advancing Industrial Efficiency

Modern drilling machines have become indispensable across multiple industries, delivering precision, efficiency, and versatility. By exploring the latest exhibits at ITES China, we offer a comprehensive view of how these machines transform manufacturing processes. From automotive to aerospace and medical sectors, adopting advanced China drilling machine solutions allows companies to achieve consistent quality and enhanced productivity. Our exhibition serves as a bridge between industry professionals and leading drilling machine manufacturers, ensuring that innovative drilling technologies continue to support industrial growth and operational excellence. By embracing these solutions, we can create a more sustainable and efficient industrial ecosystem that meets the evolving demands of modern manufacturing.