2-Micron Precision! What Makes High-Speed Stamping for Automotive Connectors So Challenging?

【Introduction】 Automotive Connectors、Connection Technology、Vehicle Body Electronic System

A conventional gasoline-powered vehicle uses approximately 500 connectors, while a new energy vehicle (NEV) requires over 1,000—distributed across critical components like engines, transmissions, batteries, sensors, and autonomous driving systems, responsible for transmitting power and signals.

As a key component in this niche sector, automotive connectors are in a growth phase marked by simultaneous increases in volume and price. The high-speed stamping process behind them has thus become a core competitive arena for midstream manufacturing enterprises.

01 | A Blue Ocean in the Red Ocean Market: Opportunities in Automotive Electronic Connectors

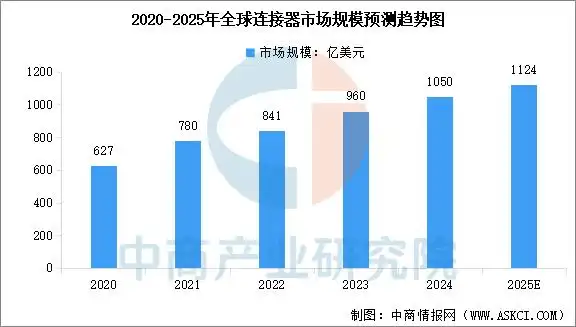

According to data from the China Business Research Institute, the global connector market grew from 62.7billionin2020to105 billion in 2024, with a compound annual growth rate (CAGR) of 13.8% during the period. The market is projected to reach $112.4 billion in 2025.

As the world’s largest producer and consumer of NEVs, China has emerged as a key growth driver for the global automotive connector market. China accounts for over 40% of the global connector market share. In 2024, the Chinese automotive connector market grew to ¥57.142 billion and is expected to reach ¥62.397 billion in 2025.

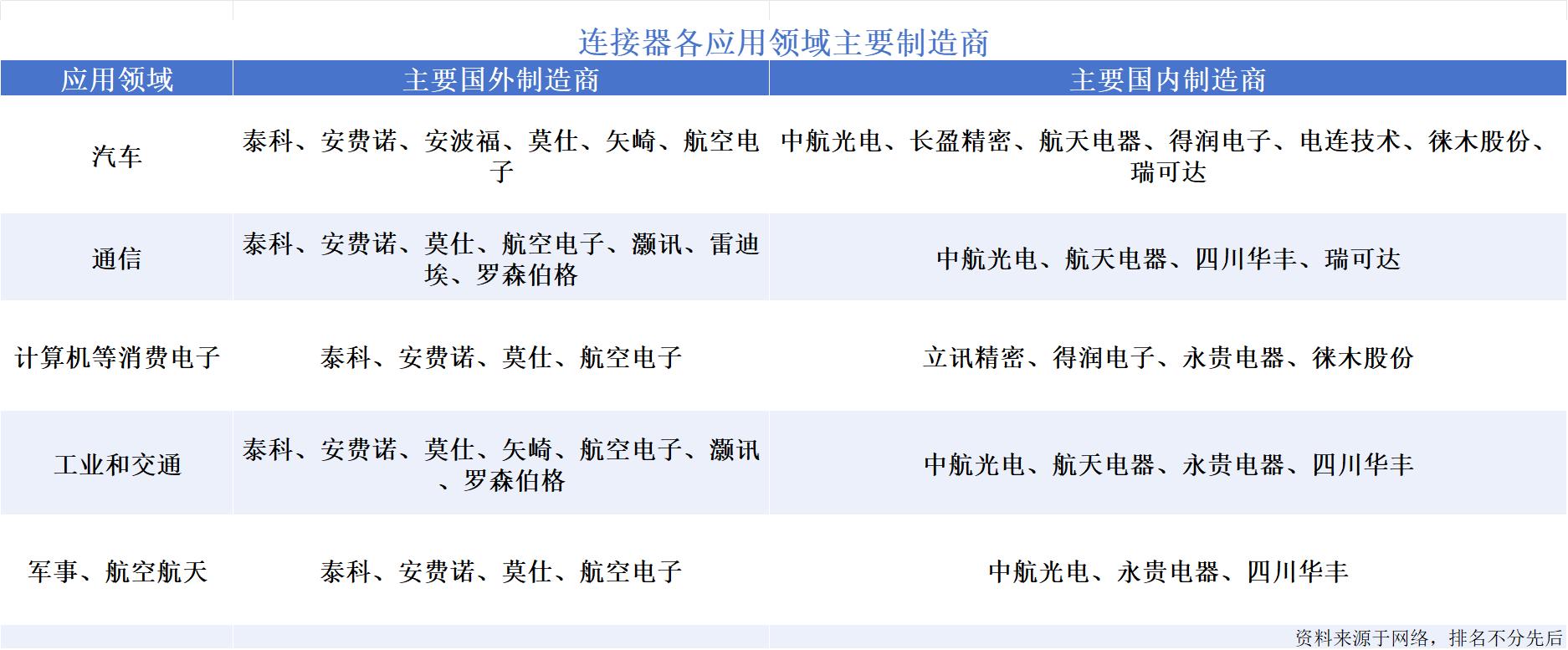

While the global market remains dominated by international giants like TE Connectivity, Amphenol, Molex, and Rosenberger in the high-end segment, domestic players such as AVIC Jonhon, Recodeal, and Yonggui Electric are strengthening their competitiveness through continuous technological innovation and product upgrades, gradually narrowing the gap with global leaders. Data indicates that the localization rate is projected to accelerate from 8% in 2021 toward 35% in 2025.

02 | Why Precision Matters in Connector Manufacturing (Down to the Millimeter)

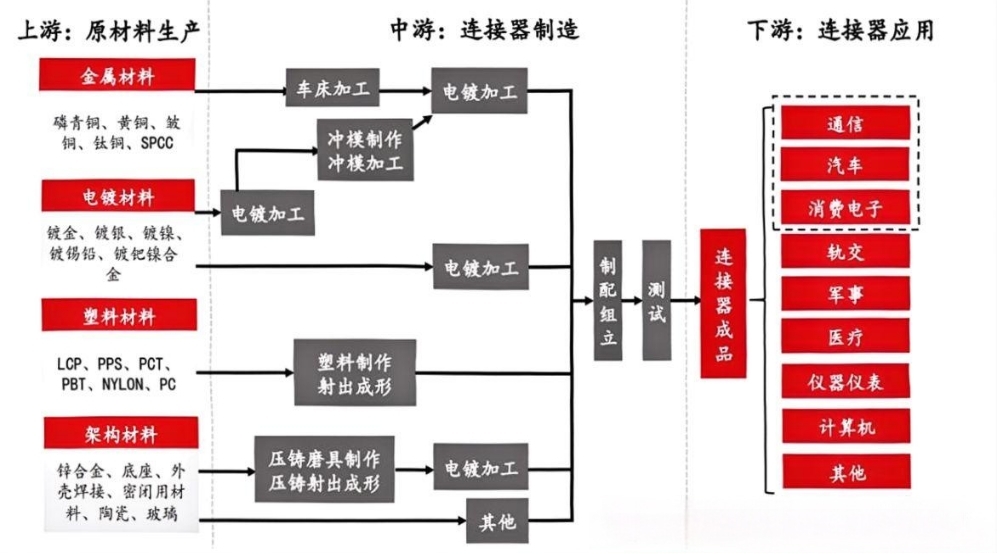

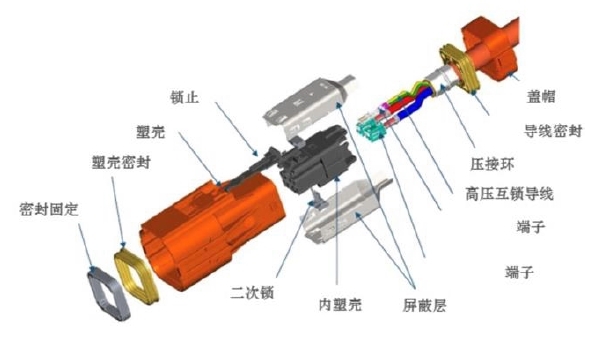

Automotive connectors are primarily categorized into three types: low-voltage/low-speed connectors, high-voltage connectors, and high-frequency/high-speed connectors. Their production typically involves five core stages: material selection, high-speed stamping, electroplating, surface treatment, and assembly testing.

Among these, high-speed stamping—critical for shaping key components—directly determines connector precision, reliability, and production efficiency, making it the linchpin of the entire manufacturing process.

High-speed stamping is the most technically demanding stage in connector manufacturing, used to produce core metal parts like terminals, contact springs, pins, and shielding cases. The precision of these parts directly impacts contact performance, signal transmission efficiency, and mechanical lifespan.

· Terminals (core conductive components) require stable current/signal transmission, with dimensional tolerances controlled within ±0.003 mm and surface roughness Ra ≤ 0.2 μm to avoid poor contact due to deviations.

· Contact springs (made of elastic materials like beryllium copper) need complex curved structures via high-speed stamping, with an elastic modulus of 100–120 GPa to ensure an insertion/extraction lifespan exceeding 5,000 cycles.

· Pins (for signal transmission) typically have diameters of 0.3–1.0 mm, requiring straightness deviation < ±0.002 mm to prevent jamming or contact failure during insertion.

· Shielding cases (for electromagnetic shielding) must achieve a 360° fully enclosed structure via high-speed stamping, with burrs on cut edges ≤ 3 μm, flatness ≤ 0.002 mm/m, and electromagnetic shielding effectiveness ≥ 60 dB.

Achieving these requirements relies heavily on high-speed precision presses. Traditional presses with manual operation suffer from slow speeds (200–400 strokes per minute, SPM), limited daily output, unstable precision due to manual feeding and mold wear, high defect rates, and costly post-production sorting and mold repair.

In contrast, high-speed precision presses demand ultra-high precision control and stable high-speed operation to prevent material deformation or mold wear. Despite advancements in high-speed stamping technology, matching upstream and downstream demands remains a challenge for midstream manufacturers. To meet NEV industry needs for “large-volume, high-quality, low-cost” production and adapt to centralized, intelligent electronic/electrical architectures, high-speed precision presses face ongoing hurdles:

· Difficulty in dimensional tolerance control: Miniaturized components (e.g., terminals as narrow as 0.2 mm) are prone to deviations with traditional methods, requiring micron-level control from high-speed precision presses.

· Conflict between material utilization and forming quality: Springback and warpage during high-speed stamping affect quality, while prioritizing quality may reduce material utilization—requiring optimization of mold design and stamping parameters.

· Mold wear and lifespan management: High-frequency friction between molds and metals causes wear, impacting precision. Carbide molds and surface coating technologies extend mold life.

· Ensuring consistency in mass production: Large NEV connector orders demand uniform part performance, imposing stringent requirements on press stability and intelligent detection capabilities.

03 | How Do Key Equipment Play Their Role?

Overcoming these challenges requires not only process optimization but also upgrades in high-precision stamping equipment.

Solutions from leading manufacturers illustrate this trend. Bruderer, a leader in precision stamping equipment, has introduced innovations tailored to miniaturized, high-precision connector components. Its globally pioneering “dynamic closed-loop correction technology for the bottom dead center” enhances stamping precision to within 2 microns, redefining industry standards. The BSTA series presses feature modular design and intelligent control systems, achieving over 2,500 SPM with high precision while reducing energy consumption by 30%.

Yamada Dobby’s X2S-18 high-speed precision press reaches 5,000 SPM with a 180 kN pressing capacity and a variable stroke structure (0–15 mm stepless adjustment), improving forming adaptability and mold compatibility for NEV connector manufacturing.

Series Presses, Image source Internet.png)

Kyoritsu Machinery’s SS series precision automatic presses offer die height adjustment accurate to 0.01 mm (digital display), double crank mechanisms, and eccentric load resistance. Its ANEX (II) series uses toggle link mechanisms for reduced thermal displacement, fewer chip jumps, and better coining effects—ideal for high-speed connector stamping. Additionally, Kyoritsu’s GX series high-speed precision feeders provide accurate feeding, soft-touch buttons, and scratch-proof handles, benefiting automated production of tiny connector parts.

Notably, these companies will showcase their latest products and solutions at the ITES Shenzhen Industrial Exhibition in late March next year. ITES Shenzhen Industrial Exhibition’s affiliated themed exhibition—Metal Sheet & Tube Processing Technology Show—addresses extreme challenges in cost reduction and efficiency improvement for metal sheet/tube processing in sectors including NEVs, automotive manufacturing, communication electronics & servers, machinery manufacturing, and sheet metal/metal products. It showcases cutting-edge technologies, equipment, and automated/intelligent solutions for sheet metal stamping, welding, tube/profile processing, stainless steel processing, and surface treatment, offering a one-stop technical docking platform for the industrial chain. (Click “Read More” at the end for exhibition details.)

If you aim to enter the automotive connector market, showcase innovative stamping solutions, or connect with leading manufacturers like TE Connectivity, Amphenol, Luxshare Precision, and Derun Electronics to explore collaborations, scan the QR code below to contact us and secure your premium booth at the exhibition immediately!