Maximizing Productivity with Advanced Tool Magazines in CNC Machines

【Introduction】 Maximizing Productivity with Advanced Tool Magazines in CNC Machines

Industrial output often depends on unseen components that orchestrate efficiency behind the scenes. Among these, the tool magazine functions as a critical subsystem in modern CNC equipment. This unit, often called a CNC tool magazine, directly influences machine uptime, flexibility, and overall operational capacity. At ITES Shenzhen, we analyze how advancements in this core component are redefining production limits, transforming it from a passive storage unit into an active productivity engine.

The Role of the Tool Magazine in Automated Production

A CNC tool magazine is more than a simple rack for holding cutters. It is an integrated automated system responsible for the secure storage, rapid selection, and precise exchange of tools during the machining cycle. The design and capability of the tool magazine determine a machine's ability to perform complex, multi-step operations without manual intervention. Key performance metrics include storage capacity, tool change speed, reliability, and the accuracy of tool positioning. A high-performance CNC tool magazine minimizes non-cutting time, allowing the spindle to remain engaged in material removal. This is especially critical for machining complex parts requiring dozens of tools, where the efficiency of the tool magazine becomes a primary bottleneck or a significant advantage in the total production timeline.

Innovation and Supply Chain Advantages in Core Components

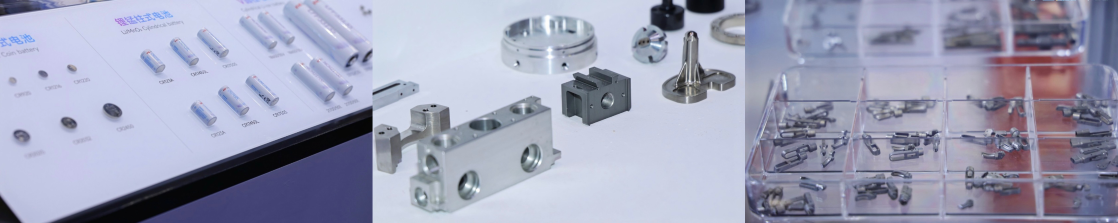

The evolution of the tool magazine reflects broader trends in precision and reliability. Progress in drive mechanisms, tool identification systems, and collision-avoidance technology has made these units faster and more dependable. Within the global supply chain, specialized Chinese manufacturers have developed considerable expertise in producing these and other core functional components. Their focus extends beyond the CNC tool magazine to include integrated solutions involving spindles, rotary tables, and linear guides. This concentrated ecosystem allows for synergistic development, where the performance of the tool magazine is optimized alongside the machine's other core systems. For equipment manufacturers and end-users, this supply chain offers access to high-precision component solutions that meet stringent demands across sectors like automotive and medical devices, often with advantages in system compatibility and technical support.

Evaluating Advanced Solutions at ITES Shenzhen

Understanding the tangible impact of an advanced tool magazine requires direct engagement with the technology. The Core Functional Components zone at ITES Shenzhen is engineered for this purpose. This dedicated exhibition segment focuses on the high-end equipment industry chain, presenting the subsystems that define machine performance. Here, attendees can interact with a wide array of CNC tool magazine designs, from compact drum-type magazines to large-capacity chain-style systems, displayed by dozens of specialized suppliers. At ITES Shenzhen, engineers can compare the build quality, exchange mechanisms, and control interfaces of various tool magazine units side-by-side. Discussions with exhibitor technicians provide insights into integration challenges, maintenance protocols, and customization options for specific machining applications.

The selection of a CNC tool magazine is a strategic decision that affects long-term productivity. Observing these core components in the context of the complete manufacturing ecosystem at ITES Shenzhen provides a necessary perspective. The exhibition enables a thorough technical evaluation, connecting professionals with the innovators who are pushing the boundaries of storage capacity, change speed, and system intelligence. This direct access to specialized knowledge and hardware is how manufacturing teams can make informed decisions to upgrade their capabilities, ensuring their CNC assets are supported by a tool magazine system designed for maximum throughput and minimal downtime in a competitive production environment.