Integrating Spindles and Rotary Tables for Complex Part Machining

【Introduction】 Integrating Spindles and Rotary Tables for Complex Part Machining

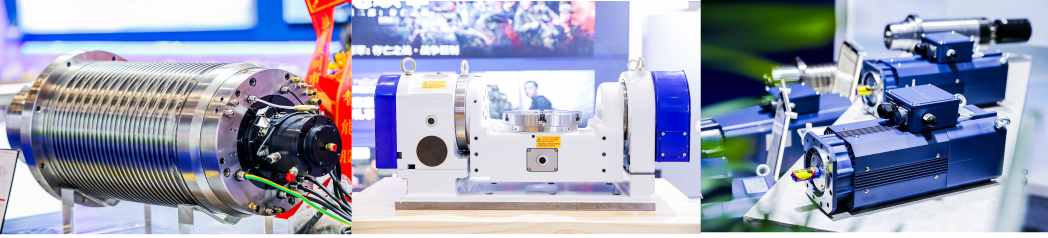

Producing intricate components with complex geometries, such as those found in aerospace assemblies or medical implants, requires machining capabilities beyond three linear axes. The creation of contours, undercuts, and multi-sided features on a single workpiece necessitates synchronized rotational and linear movement. This is achieved through the precise integration of two core functional components: the China cnc spindle and the rotary table. Their combined operation transforms a standard machining center into a versatile system capable of complete, multi-face machining in a single setup, which is a fundamental requirement for advanced manufacturing sectors.

The Technical Synergy in Multi-Axis Machining

A China cnc spindle provides the high-speed rotational force for cutting tools, dictating the machine's power, speed range, and thermal stability—all critical for surface finish and accuracy. A rotary table, on the other hand, provides the fourth or fifth axis of motion by precisely rotating the workpiece itself. When these two systems are integrated under unified CNC control, their synergy unlocks new possibilities. The spindle can approach the workpiece from virtually any angle, allowing for the machining of complex contours without the need to manually reposition the part. This reduces cumulative errors from multiple setups, ensures higher positional accuracy between features, and significantly cuts down on non-cutting time. For manufacturers of molds, impellers, or structural aerospace components, this integration provided by a proficient China cnc spindle and a precision rotary table is not merely an upgrade but a necessity for technical feasibility and economic efficiency.

Supply Chain Accessibility and Collaborative Development

The advancement and adoption of these high-precision subsystems are supported by a mature and responsive manufacturing ecosystem. A concentrated network of specialized rotary table manufacturers and spindle producers fosters an environment of rapid innovation and application-specific development. This proximity allows for close collaboration between component engineers and machine tool builders, facilitating the customization of units for specific torque, speed, or form-factor requirements. The availability of this technical expertise within the supply chain means machine integrators and end-users can access not only standard catalog items but also engage in dialogue for tailored solutions. This collaborative dynamic helps accelerate the development cycle for new machining platforms and ensures that the performance of a China cnc spindle is perfectly matched with the indexing accuracy of a rotary table from dedicated rotary table manufacturers.

Direct Evaluation of Core Components at a Specialized Event

Specifying these critical components from technical datasheets alone carries inherent risk. Assessing build quality, vibration characteristics, and control integration requires firsthand inspection. This need makes specialized industrial exhibitions an essential resource. The Core Functional Components zone at ITES Shenzhen is structured for this exact purpose. It serves as a primary venue where machine tool builders and high-precision workshops can evaluate a wide array of China cnc spindle units and engage directly with multiple rotary table manufacturers. The exhibition scope brings together the entire ecosystem, from spindles and rotary tables to the supporting architecture of linear guides and ball screws. Walking the floor of ITES Shenzhen allows engineers to compare the technical specifications and physical construction of different models, discuss thermal management strategies, and understand compatibility with existing control systems. This direct engagement is a vital step in the procurement process for components where performance directly dictates machining capability.

The capability to machine complex parts in a single setup is fundamentally reliant on the seamless integration of precise rotational components. The dynamic partnership between a high-performance China cnc spindle and an accurate rotary table defines the ceiling of a machining center's potential. Navigating the selection and integration of these subsystems is supported by a specialized industrial supply chain that encourages technical collaboration. For professionals responsible for specifying or operating advanced machine tools, a dedicated forum for evaluation and comparison is invaluable. The focused environment of ITES Shenzhen provides this platform, offering a clear overview of available technologies and facilitating the connections necessary to source the core components that drive modern, complex part manufacturing forward.