Hob Cutters: Applications in Gear Manufacturing

【Introduction】 Hob Cutters: Applications in Gear Manufacturing

Gear manufacturing is a discipline defined by geometric precision and kinematic theory. The accurate formation of involute tooth profiles is fundamental for power transmission efficiency, noise reduction, and operational longevity. While multiple methods exist for creating gear teeth, hobbing remains a predominant process for its versatility and productivity. The specialized cutting tools that enable this method, hob cutters, are themselves masterpieces of tooling engineering, directly dictating the quality and economics of gear production.

The Technical Function and Design of Hob Cutters

A hob cutter is a helical cutting tool that operates in a continuous generating mesh with the gear blank. Its design is a complex interpolation of flute geometry, rake angle, clearance, and precise gashing. As the hob and workpiece rotate in synchronized motion, each cutting edge progressively removes material to form the gear tooth space. The accuracy of the final gear—its profile, pitch, and lead—is inherently tied to the precision of the hob's own tooth form and its correct installation. Modern hob cutters are engineered for specific materials, from standard steels to challenging alloys, and are often coated with advanced materials to manage heat and wear. Their performance determines not just gear quality but also key production metrics like cutting speed, feed rates, and tool life between regrinds.

The Ecosystem for Advanced Tooling Manufacture

The capability to produce high-performance hob cutters rests on a foundation of specialized manufacturing knowledge. This encompasses advanced metallurgy for substrate materials, precise CNC grinding for profile generation, and controlled deposition processes for coating application. A concentrated network of tooling specialists has developed expertise across this entire value chain. For gear manufacturers, this integrated supply ecosystem offers significant advantages. It enables closer collaboration on custom tool designs for unique gear profiles or specific production challenges. The proximity of material suppliers, precision grinders, and coating service providers facilitates faster iteration and problem-solving, reducing lead times for both standard and specialized tooling. This cohesive structure supports the consistent supply of the critical hob cutters that drive modern gear production.

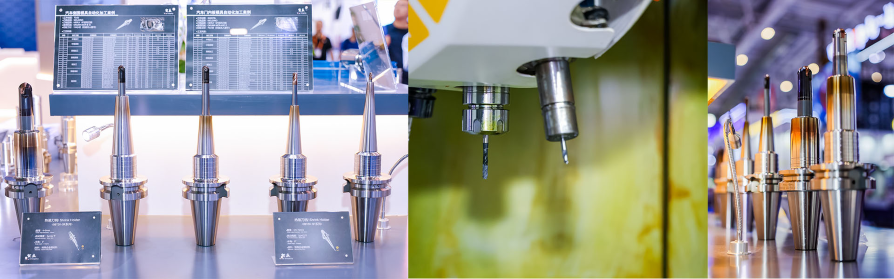

The Convergence Point for Tooling Solutions at ITES China

Selecting and optimizing tooling is a practical decision that benefits from direct examination and technical exchange. The Tools zone at ITES China is designed as this essential forum. Recognized as the "Teeth of Industry," this zone aggregates a comprehensive range of cutting solutions. Within this focused environment, gear manufacturing professionals can engage with multiple specialists. The exhibition scope explicitly includes hobs, allowing visitors to compare products from different hob cutters manufacturers, discuss substrate and coating options, and examine supporting tooling like precision tool holders. Furthermore, the zone presents the complete ecosystem, from milling cutters and carbide tools to the vital tool grinding machines necessary for hob maintenance and reconditioning. At ITES China, conversations move from catalog specifications to applied solutions, addressing real-world goals of cost control and efficiency gains in gear machining.

The production of reliable and efficient gears is inextricably linked to the quality and application of the cutting tools used. Hob cutters represent a critical, sophisticated element in this manufacturing sequence. The depth and integration of the industrial network dedicated to producing these tools provide a stable foundation for gear makers globally. For those engaged in specifying, purchasing, or optimizing these essential tools, dedicated industrial platforms offer a necessary interface between need and solution. ITES China functions as this interface, bringing the science of tooling into a practical, accessible environment where the tools that manufacture the gears can be evaluated, understood, and sourced.